June 2021

Service and Repair Manual

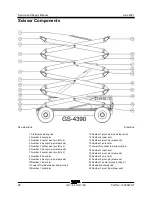

Scissor Components

Part No. 1306587GT

GS

™

-84 • GS

™

-90

31

28 Remove the pin retaining fasteners from both

number 3 pivot pins (index #19) at the steer

end of the machine. Do not remove the pins.

29 Use a slide hammer to remove both number

3 pivot pins (index #6) from the non-steer end

of the machine.

30 Use a slide hammer to remove both number

3 pivot pins (index #19) from the steer end of

the machine.

31 Carefully remove the number 3 inner and

outer arms (index #18 and #16) from the

machine.

Crushing hazard. The number

3 inner and outer arms could

become unbalanced and fall

when they are removed from the

machine if not properly

supported by the overhead

crane.

Note: If further disassembly of the scissor arm pair

is required, refer to Repair Procedure,

How to

Disassemble a Scissor Arm Pair.

32 Secure the non-steer end of the number

2 inner and outer arms (index #8 and #20)

and the non-steer end of the number 1 inner

and outer arms (index #10 and #12) together

with a strap or other suitable device.

33 Attach a lifting strap from an overhead crane

to the number 1 outer arm (index #12) at the

non-steer end of the machine. Do not apply

any lifting pressure.

34 Remove the pin retaining fasteners from the

number 1 pivot pins (index #13) at the non-

steer end of the machine.

35 Use a slide hammer to remove both number

1 pivot pins (index #13) from the non-steer

end of the machine.

36 Carefully lift the number 1 outer arm at the

non-steer end approximately 15 inches /

40 cm.

37 Place a 6 x 6 x 32 inch / 15 x 15 x 80 cm long

block across both sides of the chassis under

the barrel end of the lift cylinder.

38 Lower the number 1 outer arm (index #12)

onto the block.

Crushing hazard. Keep hands

clear of moving parts when

lowering the arms onto the

block.

39 Attach a lifting strap from an overhead crane

to the lifting eyes on the lift cylinder.

40 Remove the lift cylinder barrel-end pivot pin

retaining fasteners.

41 Use a soft metal drift to remove the lift

cylinder barrel-end pivot pin (index #11).

42 Carefully remove the lift cylinder from the

machine.

Crushing hazard. The lift

cylinder could become

unbalanced and fall when it is

removed from the machine if not

properly supported by the

overhead crane.

43 Carefully lift the number 1 outer arm (index

#12) approximately 2 inches / 5 cm and

remove the block.

44 Lower the number 1 outer arm (index #12)

onto the slide blocks.

Crushing hazard. Keep hands

clear of moving parts when

lowering the arms onto the

block.

45 Secure the number 1 outer arm (index #12) to

the slide blocks.

Summary of Contents for Genie GS-3384

Page 185: ...June 2021 Service and Repair Manual 171 Ford MSG 425 Engine Wire Harness...

Page 188: ...Service and Repair Manual June 2021 174 Deutz D 2 9 L4 Engine Wire Harness...

Page 189: ...June 2021 Service and Repair Manual 175 Deutz TD 2 2 L3 Engine Wire Harness...

Page 192: ...Service and Repair Manual June 2021 178 Deutz TD 2 2 L3 Engine Wire Harness...

Page 193: ...June 2021 Service and Repair Manual 179 Hydraulic Schematic...

Page 194: ...Service and Repair Manual June 2021 180 GS 84 GS 90 Part No 1306587GT Hydraulic Schematic...

Page 195: ...June 2021 Service and Repair Manual Part No 1306587GT GS 84 GS 90 181 Hydraulic Schematic...

Page 196: ...Service and Repair Manual June 2021 182 Hydraulic Schematic...

Page 197: ...June 2021 Service and Repair Manual 183 Electrical Schematic Ford Engine Models ANSI CSA...

Page 200: ...Service and Repair Manual June 2021 186 Electrical Schematic Ford Engine Models ANSI CSA...

Page 201: ...June 2021 Service and Repair Manual 187 Electrical Schematic Deutz Engine Models ANSI CSA...

Page 204: ...Service and Repair Manual June 2021 190 Electrical Schematic Deutz Engine Models ANSI CSA...

Page 206: ...Service and Repair Manual June 2021 192 Electrical Schematic SCON ANSI CSA...

Page 207: ...June 2021 Service and Repair Manual 193 Electrical Schematic Ford Engine Models AS CE...

Page 210: ...Service and Repair Manual June 2021 196 Electrical Schematic Ford Engine Models AS CE...

Page 211: ...June 2021 Service and Repair Manual 197 Electrical Schematic Deutz Engine Models AS CE...

Page 214: ...Service and Repair Manual June 2021 200 Electrical Schematic Deutz Engine Models AS CE...

Page 217: ......