June 2021

Service and Repair Manual

Scissor Components

Part No. 1306587GT

GS

™

-84 • GS

™

-90

33

61 Attach a lifting strap from an overhead crane

to the number 1 inner and outer arms (index

#10 and #12) at the non-steer end of the

machine. Do not apply any lifting pressure.

62 Remove the pin retaining fasteners from both

chassis centering link pivot pins (index #23) at

the number 1 inner arm.

63 Place a rod through each chassis centering

link pivot pin and twist to remove the pin. Rest

the centering links on the chassis.

64 Remove the pin retaining fasteners from the

number 1 inner arm slide blocks (index #24)

at the steer end of the machine.

65 Use a slide hammer to remove the number

1 inner arm slide block pivot pins (index #24).

66 Use a slide hammer to remove the number

1 outer arm slide block pivot pins (index #24)

at the non-steer end of the machine.

67 Carefully remove the number 1 inner and

outer arms (index #10 and #12) from the

machine.

Crushing hazard. The number

1 inner and outer arms could

become unbalanced and fall

when they are removed from

the machine if not properly

supported by the overhead

crane.

Note: If further disassembly of the scissor arm pair

is required, refer to Repair Procedure,

How to

Disassemble a Scissor Arm Pair.

How to Disassemble a Scissor Arm Pair

How to Disassemble a Scissor

Arm Pair

Bodily injury hazard. This

procedure requires specific repair

skills, lifting equipment and a

suitable workshop. Attempting

this procedure without these

skills and tools could result in

death or serious injury and

significant component damage.

Dealer service is strongly

recommended.

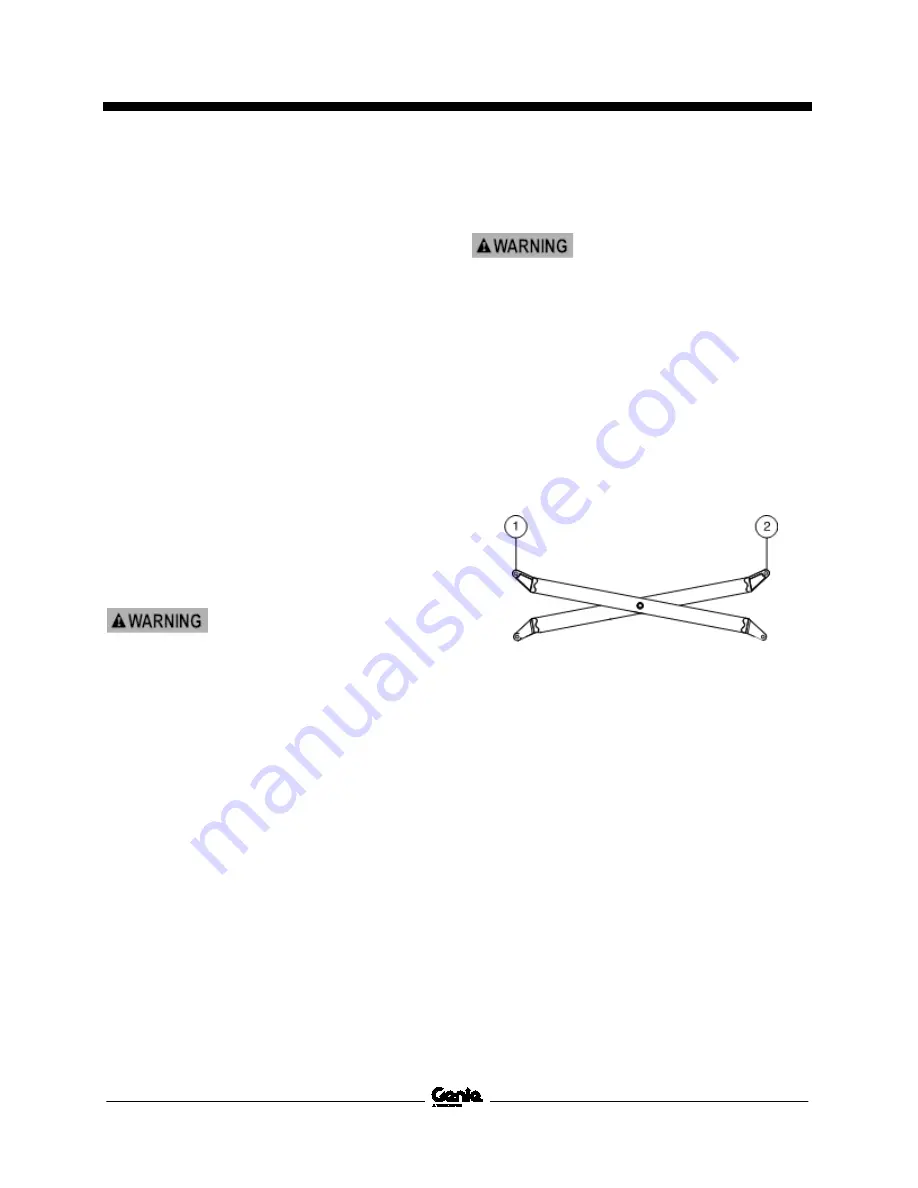

1 Attach a lifting strap from an overhead crane

to the end of the outer arm.

Note: Attach the lifting strap to the end of the

scissor arm that has the casting pointing upwards.

1 outer arm

2 inner arm

2 Attach a lifting strap from a second overhead

crane to the end of the inner arm.

Note: Attach the lifting strap to the end of the

scissor arm that has the casting pointing upwards.

3 Raise the scissor arms with the overhead

cranes approximately 12 inches / 30 cm.

Summary of Contents for Genie GS-3384

Page 185: ...June 2021 Service and Repair Manual 171 Ford MSG 425 Engine Wire Harness...

Page 188: ...Service and Repair Manual June 2021 174 Deutz D 2 9 L4 Engine Wire Harness...

Page 189: ...June 2021 Service and Repair Manual 175 Deutz TD 2 2 L3 Engine Wire Harness...

Page 192: ...Service and Repair Manual June 2021 178 Deutz TD 2 2 L3 Engine Wire Harness...

Page 193: ...June 2021 Service and Repair Manual 179 Hydraulic Schematic...

Page 194: ...Service and Repair Manual June 2021 180 GS 84 GS 90 Part No 1306587GT Hydraulic Schematic...

Page 195: ...June 2021 Service and Repair Manual Part No 1306587GT GS 84 GS 90 181 Hydraulic Schematic...

Page 196: ...Service and Repair Manual June 2021 182 Hydraulic Schematic...

Page 197: ...June 2021 Service and Repair Manual 183 Electrical Schematic Ford Engine Models ANSI CSA...

Page 200: ...Service and Repair Manual June 2021 186 Electrical Schematic Ford Engine Models ANSI CSA...

Page 201: ...June 2021 Service and Repair Manual 187 Electrical Schematic Deutz Engine Models ANSI CSA...

Page 204: ...Service and Repair Manual June 2021 190 Electrical Schematic Deutz Engine Models ANSI CSA...

Page 206: ...Service and Repair Manual June 2021 192 Electrical Schematic SCON ANSI CSA...

Page 207: ...June 2021 Service and Repair Manual 193 Electrical Schematic Ford Engine Models AS CE...

Page 210: ...Service and Repair Manual June 2021 196 Electrical Schematic Ford Engine Models AS CE...

Page 211: ...June 2021 Service and Repair Manual 197 Electrical Schematic Deutz Engine Models AS CE...

Page 214: ...Service and Repair Manual June 2021 200 Electrical Schematic Deutz Engine Models AS CE...

Page 217: ......