STARTING THE ENGINE

• Set the forward/back speed lever to neutral

position.

• To start the engine, rotate the ignition switch to

position

, and release when the engine starts.

If the engine does not start within 20 seconds,

release the key and wait at least 2 minutes before

attempting again.

• After the engine starting,

slow down the rpm and

wait some seconds

before engaging a

gear; this allows for a

gradual warm up of the

engine oil and a better

lubrication.

• In case of engine jump-

starting, remove the

connecting cables (see following chapter).

NOTICE

If the light indicators do not switch off/on when

engine is running, immediately stop the machine

and find and rectify the fault.

WARNING

Once it has been started, the engine continues to

run even if you leave the driving place. DO NOT

LEAVE THE DRIVING PLACE BEFORE HAVING

SHUT THE ENGINE DOWN, LOWERED THE BOOM

TO THE GROUND, TURNED THE SPEED SWITCH

TO THE NEUTRAL POSITION AND ENGAGED

THE PARKING BRAKE.

Engine can not be started if the speed switch is

not in the neutral position.

JUMP-STARTING THE ENGINE

NOTICE

Do not start the engine using a quick charge

booster to avoid any damage to the electronic

boards.

DANGER

When jump-starting the engine through the

battery of another machine, make sure that the

two vehicles cannot collide to prevent formation

of sparks. Batteries give off a flammable gas and

sparks may burn it and cause an explosion

Do not smoke when checking the electrolyte

level.

Keep any metal object like buckles, watch

straps, etc. clear of the battery positive (+)

terminal. These elements can short between

the terminal and nearby metal work and the

operator can get burned.

The booster supply must have the same rated

voltage and output of the battery installed on

the handler.

To jump-start the engine:

• Turn any users off by the special control levers.

• Put the gear lever to neutral and engage the

parking brake.

• Ensure the machine battery

A

is connected to

the frame earth, the terminals are well tightened

and the electrolyte level is regular.

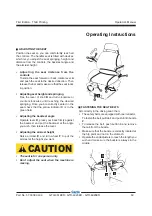

• Connect the two batteries as shown in the

figure. Connect first the positive terminals of the

two batteries, then the negative terminal of the

booster supply

B

to the machine frame earth.

• If the booster supply is installed on a second

vehicle, make sure that the latter does not touch

the handler.

To avoid damage to the electronic

instruments of the machine, the engine of

the machine where the booster supply is

installed, must be stopped.

Operating Instructions

Part No. 57.0009.0404 GTH-4518ER - GTH-4020ER - GTH-6025ER 65

Operator’s Manual

First Edition - Third Printing

Summary of Contents for Genie GTH-4020 ER

Page 188: ......