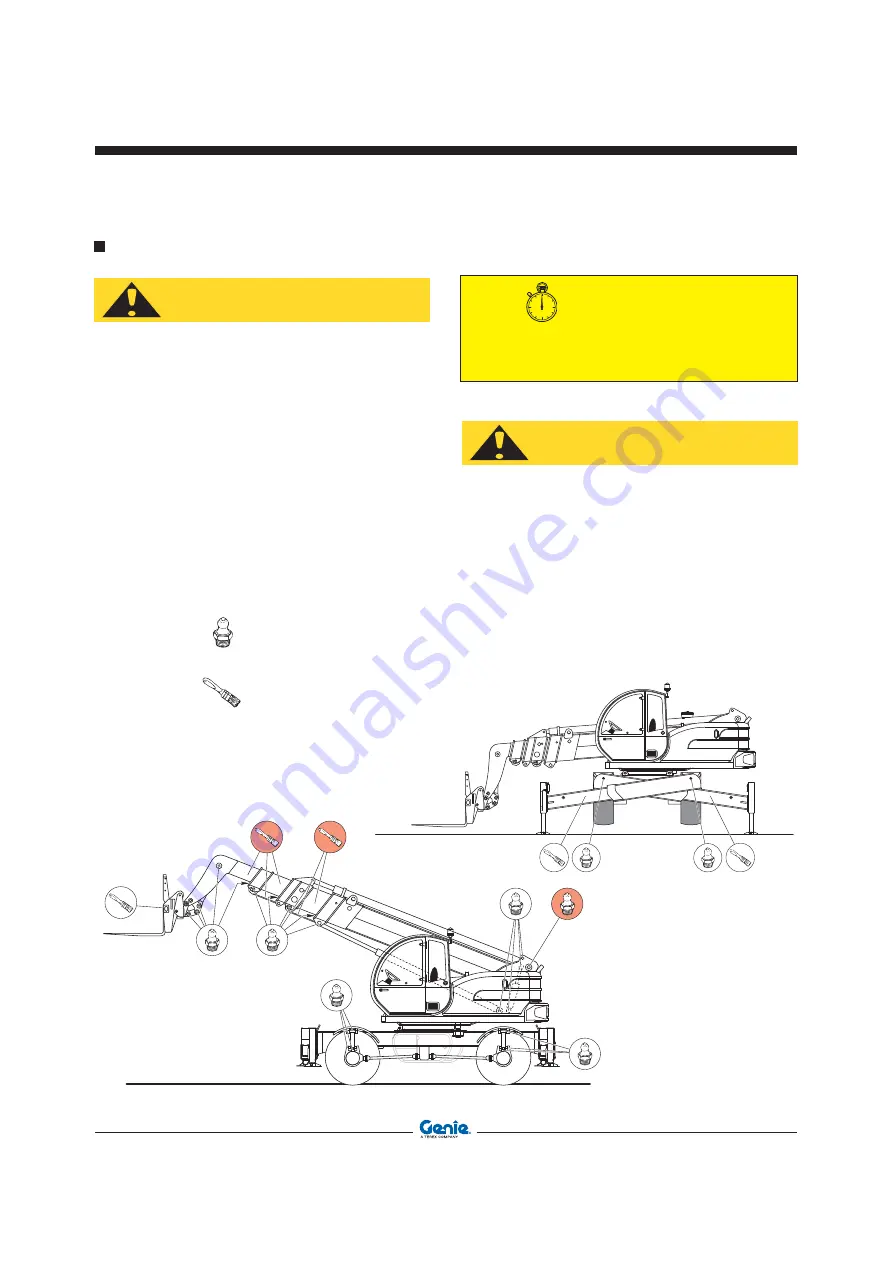

Maintenance

GREASING

CAUTION

Before injecting grease into the greasers,

thoroughly clean them to avoid that mud, dust

or other matters can mix with the lubricant and

reduce or annihilate the lubrication effect.

Remove any old grease with a degreaser from

the telescopes before smearing them with new

grease.

Regularly grease the machine to grant it efficient

conditions and a long life.

By means of a pump, inject grease into the special

greasers.

As the fresh grease comes out, stop the operation.

The greasing points are shown in the following

figures:

- the symbol

represents the points to be

greased by a pump

- the symbol

represents the points to be

greased by a brush.

SERVICE INTERVAL

Running-in

__________________________ None

Ordinary __________________

Every

10

hours

CAUTION

Use only PTFE INTERFLON FIN GREASE LS 2

to lubricate the sliding parts of the telescopic

section. Observe the following schedule:

• After the first 50 operating hours (1 week)

• After the first 250 operating hours (1 month)

• Every 1000 operating hours (6 months)

Remove any old grease from the boom and

smear the sliding area of the blocks with a thin

coat of grease.

Part No. 57.0009.0404 GTH-4518ER - GTH-4020ER - GTH-6025ER 95

Operator’s Manual

First Edition - Third Printing

Summary of Contents for Genie GTH-4020 ER

Page 188: ......