April 2019

18 GTH-5519 Part No.

57.0009.0619GT

Fourth Edition - Third Printing

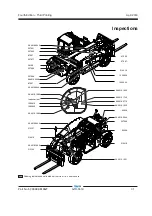

Controls

%5$.(

2,/

3

8

2*

22

7

14

4

1

18

26 10

13

17

27

12

5

9

23

6

11

15

21

16

19

20

24

25

28

2*

*NOTE: The horn button 2 is positioned at the end of the transmission control lever up to machine serial

number GTH55M-10886.

The horn button 2 is positioned at the centre of the steering wheel from machine serial number

GTH55M-10887 and GTH55M-10851, GTH55M-10854, GTH55M-10860, GTH55M-10862,

GTH55M-10863, GTH55M-10864, GTH55M-10866, GTH55M-10867, GTH55M-10869, from

GTH55M-10872 to GTH55M-10882, and GTH55M-10884,GTH55M-10885.