May 2015

Second Edition - First Printing

Part No. 57.0009.0607

GTH 4016 R - GTH 4018 R - GTH-5021 R 63

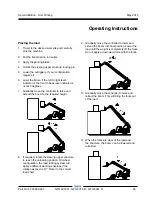

Placing the load

1

Travel to the desired work site and carefully

stop the machine.

2

Put the transmission in neutral.

3

Apply the parking brake.

4

Unlock the slewing upper structure locking pin.

5

Lower the outriggers, if your configuration

requires it.

6

Level the frame, if the left to right level

indicator or the front to back level indicator is

not at 0 degrees.

7

Gradually move the controller to raise and

extend the boom to the required height.

8

If required, rotate the slewing upper structure

to reach the unloading position. On wheel

configuration, the load limiting system will

apply a different working envelope if the

rotation /-10°. Refer to the correct

load chart.

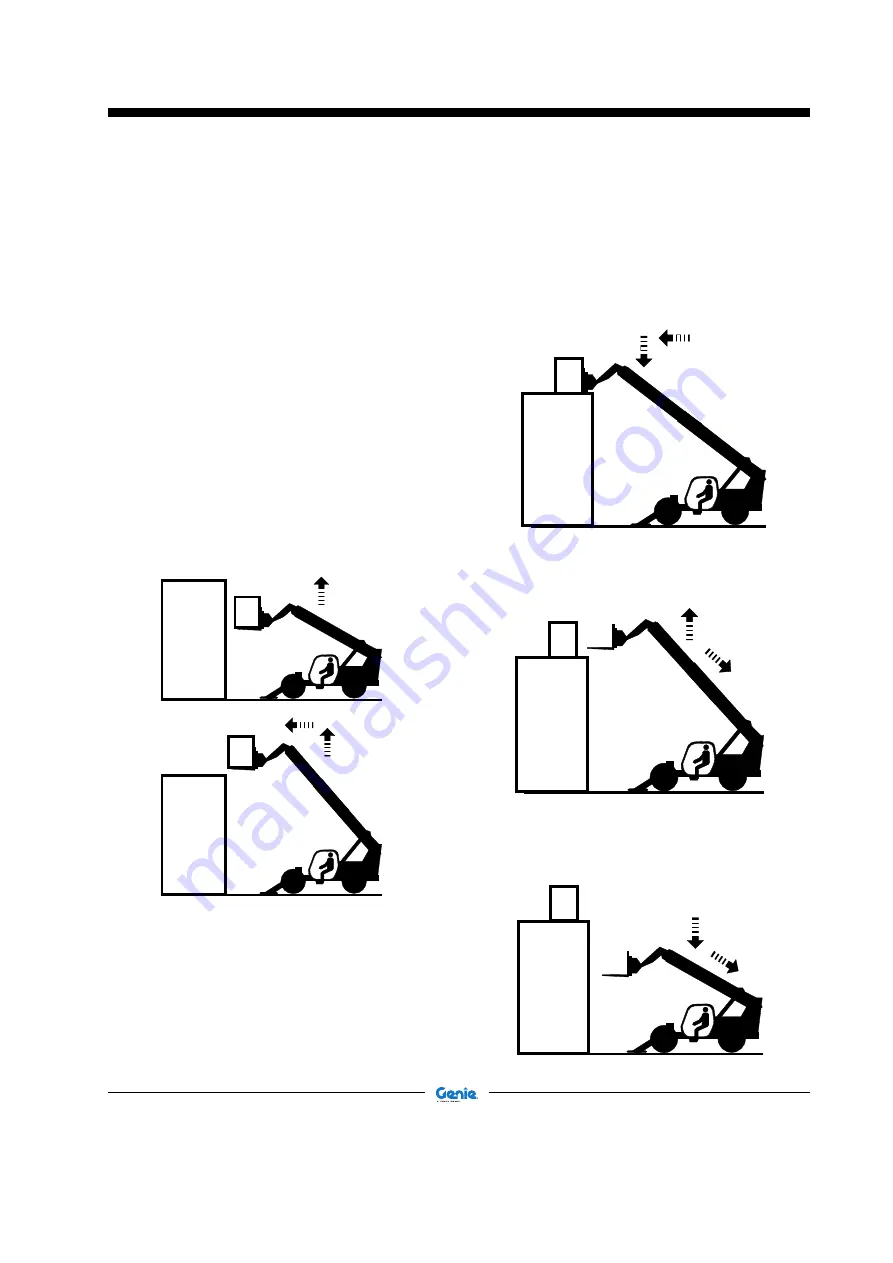

9

Gradually move the controller to lower and

extend the boom into final position. Lower the

load until the weight is completely off the forks.

Do not apply a downward force with the forks.

10 Gradually move the controller to raise and

retract the boom. This will bring the forks out

of the load.

11 When the forks are clear of the load and

the structure, the boom can be lowered and

retracted.

Operating Instructions