May 2015

72 GTH 4016 R - GTH 4018 R - GTH-5021 R Part No. 57.0009.0607

Second Edition - First Printing

Moving a disabled machine

Tow the machine only when no alternative is possible,

since this operation may result in serious damage to

the transmission. When possible, repair the machine

on site.

When the machine must be towed:

1. Disable the parking brake.

2. Set the transmission to neutral (see next page).

3. Select the two-wheel steer.

4. Connect a rigid draw bar to one of the two tie

down points present on the front axle.

5. When possible, start the engine and use the

hydraulic drive and the braking system.

6. Tow the machine for short distances and at low

speed (less than 5 km/h).

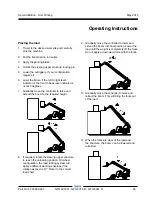

Disabling the parking brake

Use wheel chokes on all wheels to prevent

the vehicle moving once the parking brake is

disabled.

To unlock the negative brake of a faulty machine:

•

remove the three lock screws (

1

) from both

sides of the front axle, using an 8mm hex key.

Note: during this operation make sure to hold the

special screws (

2

), using a 25 mm combination

wrench.

•

Screw in the brake release screws (

3

), 1/2 turn

at a time, in sequence (

A

,

B

,

C

) until the torque

drops off sharply (4÷5 turns).

Clear the area of any personnel before remove

the locking from each of the four tires and tow

the vehicle to a suitable location.

Enabling the parking brake

Use wheel chokes on all wheels to prevent

the vehicle from moving before executing any

operation

.

To re-activate the negative brake:

•

Remove the lock screws (

1

) and unscrew all

the brake release screws (

3

) on both sides of

the front axle, until the end of stroke has been

reached (until beating against the special screws

2

). Note: do not move the special screws (

2

).

•

Assemble the lock screws (

1

) to the special

screws (

2

).

•

Lock the special screws (

2

) at 30 Nm tightening

torque and then lock screws (

1

) at 20 Nm

tightening torque on both sides.

A

C

B

u

v

w

Operating Instructions