Second Edition • First Printing

Operator's Manual

Inspections

Part No. 1297730GT

QS

™

-R12 • QS

™

-R15 • QS

™

-R20 23

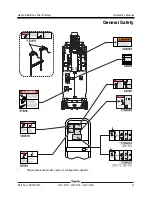

Pre-operation Inspection

Be sure that the operator’s, safety, and

responsibilities manuals are complete, legible

and in the storage container located in the

platform.

Be sure that all decals are legible and in place.

See Inspections section.

Check for hydraulic oil leaks and proper oil

level. Add oil if needed. See Maintenance

section.

Check for battery fluid leaks and proper fluid

level. Add distilled water if needed. See

Maintenance section.

Check the following components or areas for

damage, improperly installed, or missing parts and

unauthorized modifications:

Electrical components, wiring, and

electrical cables

Hydraulic power unit, reservoir, hoses,

fittings, cylinders and manifolds

Battery pack and connections

Drive motors

Tires and wheels

Ground strap

Limit switches, alarms and horn

Beacons (if equipped)

Nuts, bolts and other fasteners

Platform entry mid-rail or gate

Sequencing cables and pulleys

Wear pads

Pothole guards

Lanyard anchorage points

Work trays and bike racks (if equipped)

Brake release components

Battery cover

Mast columns and counterweight

Platform control joystick

Platform overload components

Obstruction sensing pads

Check entire machine for:

Cracks in welds or structural components

Dents or damage to machine

Excessive rust, corrosion or oxidation

Verify that all structural and other critical

components are present and all associated

fasteners and pins are in place and properly

tightened.

Note: If the platform must be raised to inspect the

machine, make sure that the battery cover is in

place to prevent the mast sections and platform

from coming down. See Operating Instructions

section.

Summary of Contents for Genie QS-12R

Page 57: ......