Part No. 1268495

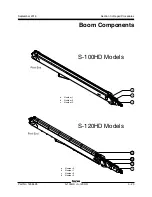

S-100HD • S-120HD

3 - 13

September 2016

Section 3 • Repair Procedures

How to Reset a Proportional

Valve Coil Default

(software version 2.00 and above)

Note: Software version 2.00 requires the use of

Web GPI to perform this procedure.

Refer to Diagnostic Codes

, Web GPI

.

Note: This procedure only needs to be performed

if a proportional valve has been replaced.

Note: After the valve coil defaults have been set,

each machine function threshold and default

function speed must be set. Refer to Repair

Procedure,

How to Set the Function Thresholds

and Default Function Speeds.

1 Open Web GPI and connect to the TCON.

2 Select the valve screen of the proportional

valve you want to reset.

Note: Choices are: Propel (drive) valve reset;

Boom up/down valve reset; Boom extend/retract

valve reset; or TT rotate valve reset.

3 Press "set Defaults" and enter the level

2 password (obtained from field service

personnel).

4 Enter "0" (zero) into the threshold boxes.

5 Press "send" and enter the level 2 password

(obtained from field service personnel).

6 Disconnect from the TCON and proceed with

calibration.

Turntable rotate functions:

Note: If the calibration fault is already displayed at

the ground box begin with step 6.

1 Turn the key switch to the off position. Confirm

the red Emergency Stop button at the platform

and ground controls is in the on position.

2 Press and hold the enter button

on the

ground control panel while turning the key

switch to platform controls. Hold the enter

button for approximately 5 seconds.

3 Press the minus button

twice, then press the

enter button

twice.

4 Use the scroll button to scroll through the

menu until

reset

turntable

rotate

joystick

defaults

is displayed. Press the

button to

select

yes

, then press the

button.

5 Exit programming mode.

Note: To exit programming mode, use the scroll

button to scroll through the menu until the

screen displays exit, then press the plus button

once, change the NO to YES, and press the enter

button

.

6 Do not start the engine.

7 Locate the primary boom/turntable rotate

joystick.

8 Move the boom/turntable joystick full stroke in

the left direction and hold for 5 seconds, then

return to the center or neutral position.

9 Move the boom/turntable joystick full stroke in

the right direction and hold for 5 seconds, then

return to the center or neutral position.

Result: The alarm at the ground controls should

sound for a successful calibration.

Result: If the alarm does not sound, repeat the

calibration procedure, beginning with step 1.

PLATFORM CONTROLS

Summary of Contents for Genie S-100HD

Page 14: ...September 2016 S 100HD S 120HD Part No 1268495 xiv This page intentionally left blank ...

Page 124: ...3 94 S 100HD S 120HD Part No 1268495 September 2016 Section 3 Repair Procedures MANIFOLDS ...

Page 126: ...3 96 S 100HD S 120HD Part No 1268495 September 2016 Section 3 Repair Procedures MANIFOLDS ...

Page 201: ...Section 5 Schematics September 2016 5 19 Electrical Schematic View 1 S 100HD Models 5 20 ...

Page 204: ...September 2016 Section 5 Schematics 5 22 Electrical Schematic View 2 S 100HD Models 5 21 ...

Page 205: ...Section 5 Schematics September 2016 5 23 Electrical Schematic View 3 S 100HD Models 5 24 ...

Page 208: ...September 2016 Section 5 Schematics 5 26 Electrical Schematic View4 S 100HD Models 5 25 ...

Page 209: ...Section 5 Schematics September 2016 5 27 Electrical Schematic View 5 S 100HD Models 5 28 ...

Page 212: ...September 2016 Section 5 Schematics 5 30 Electrical Schematic View 6 S 100HD Models 5 29 ...

Page 213: ...Section 5 Schematics September 2016 5 31 Electrical Schematic View 7 S 100HD Models 5 32 ...

Page 216: ...September 2016 Section 5 Schematics 5 34 5 33 Safety Circuit Schematic S 100HD Models ...

Page 217: ...Section 5 Schematics September 2016 5 35 5 36 Electrical Schematic View 1 S 120HD Models ...

Page 220: ...September 2016 Section 5 Schematics 5 38 Electrical Schematic View 2 S 120HD Models 5 37 ...

Page 221: ...Section 5 Schematics September 2016 5 39 Electrical Schematic View 3 S 120HD Models 5 40 ...

Page 224: ...September 2016 Section 5 Schematics 5 42 Electrical Schematic View 4 S 120HD Models 5 41 ...

Page 225: ...Section 5 Schematics September 2016 5 43 Electrical Schematic View 5 S 120HD Models 5 44 ...

Page 228: ...September 2016 Section 5 Schematics 5 46 Electrical Schematic View 6 S 120HD Models 5 45 ...

Page 229: ...Section 5 Schematics September 2016 5 47 5 48 Electrical Schematic View 7 S 120HD Models ...

Page 232: ...September 2016 Section 5 Schematics 5 50 Safety Circuit Schematic S 120HD Models 5 49 ...

Page 233: ...Section 5 Schematics September 2016 5 51 Perkins 854F 34T Engine Electrical Schematic 5 52 ...

Page 235: ...Section 5 Schematics September 2016 Part No 1268495 S 100HD S 120HD 5 53 ...

Page 236: ...September 2016 Section 5 Schematics 5 54 Perkins 854F 34T Engine Electrical Harness 5 53 ...

Page 237: ...Section 5 Schematics September 2016 5 55 Deutz TD2 9 Engine Electrical Schematic 5 56 ...

Page 240: ...September 2016 Section 5 Schematics 5 58 Deutz TD2 9 Engine Electrical Harness 5 57 ...

Page 241: ...Section 5 Schematics September 2016 5 59 Hydraulic Schematic S 100HD Models 5 60 ...

Page 248: ...September 2016 Section 5 Schematics 5 66 Hydraulic Schematic S 120HD Models 5 60 ...

Page 249: ......