3 - 26

S-100HD • S-120HD

Part No. 1268495

September 2016

Section 3 • Repair Procedures

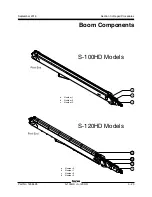

BOOM COMPONENTS

4-1

Cable Track

The cable track and boom cable tube guides

cables and hoses running up the boom. The

cable track can be repaired link by link without

removing the cables and hoses that run through

it. Removing the entire cable track assembly may

be necessary when performing major repairs that

involve removing the boom.

How to Remove the Boom

Cable Track Assembly

Note: When removing a hose assembly or fitting,

the O-ring on the fitting and/or hose end must be

replaced and then torqued to specification during

installation.

Refer to Specifications,

Hydraulic Hose and Fitting

Torque Specifications.

Note: Perform this procedure with the boom

horizontal.

1 Remove the protective cover from the platform

manifold.

2 Remove the cable track assembly end covers

from both the pivot and platform end of the

machine.

For S-100HD machines proceed to step 4.

3 Using an appropriate overhead lifting device

and beginning at the pivot end, remove the

cable track covers from the number 0 boom

tube.

4 Tag, disconnect and plug the two hydraulic

hoses from the boom pull tube to the platform

manifold. Secure them to the cable track

assembly.

Bodily injury hazard. Spraying

hydraulic oil can penetrate and

burn skin. Loosen hydraulic

connections very slowly to allow

the oil pressure to dissipate

gradually. Do not allow oil to

squirt or spray.

5 Tag and disconnect the electrical connectors

from the bottom of the control box.

6 Remove the fasteners holding the pull tube to

the number 3 boom tube.

7 Remove the fasteners holding the pull tube to

the number 2 boom tube.

8 Tag and disconnect the electrical cables located

at the platform end of the main cable track

tube on the engine side of the machine. These

cables include platform controls, limit and

proximity switches and work light (if installed).

9 Tag, disconnect and plug the platform manifold

hydraulic hoses from the bulkhead at the

platform end of the main cable track tube on

the engine side of the machine. Cap the fittings.

Bodily injury hazard. Spraying

hydraulic oil can penetrate and

burn skin. Loosen hydraulic

connections very slowly to allow

the oil pressure to dissipate

gradually. Do not allow oil to

squirt or spray.

Summary of Contents for Genie S-100HD

Page 14: ...September 2016 S 100HD S 120HD Part No 1268495 xiv This page intentionally left blank ...

Page 124: ...3 94 S 100HD S 120HD Part No 1268495 September 2016 Section 3 Repair Procedures MANIFOLDS ...

Page 126: ...3 96 S 100HD S 120HD Part No 1268495 September 2016 Section 3 Repair Procedures MANIFOLDS ...

Page 201: ...Section 5 Schematics September 2016 5 19 Electrical Schematic View 1 S 100HD Models 5 20 ...

Page 204: ...September 2016 Section 5 Schematics 5 22 Electrical Schematic View 2 S 100HD Models 5 21 ...

Page 205: ...Section 5 Schematics September 2016 5 23 Electrical Schematic View 3 S 100HD Models 5 24 ...

Page 208: ...September 2016 Section 5 Schematics 5 26 Electrical Schematic View4 S 100HD Models 5 25 ...

Page 209: ...Section 5 Schematics September 2016 5 27 Electrical Schematic View 5 S 100HD Models 5 28 ...

Page 212: ...September 2016 Section 5 Schematics 5 30 Electrical Schematic View 6 S 100HD Models 5 29 ...

Page 213: ...Section 5 Schematics September 2016 5 31 Electrical Schematic View 7 S 100HD Models 5 32 ...

Page 216: ...September 2016 Section 5 Schematics 5 34 5 33 Safety Circuit Schematic S 100HD Models ...

Page 217: ...Section 5 Schematics September 2016 5 35 5 36 Electrical Schematic View 1 S 120HD Models ...

Page 220: ...September 2016 Section 5 Schematics 5 38 Electrical Schematic View 2 S 120HD Models 5 37 ...

Page 221: ...Section 5 Schematics September 2016 5 39 Electrical Schematic View 3 S 120HD Models 5 40 ...

Page 224: ...September 2016 Section 5 Schematics 5 42 Electrical Schematic View 4 S 120HD Models 5 41 ...

Page 225: ...Section 5 Schematics September 2016 5 43 Electrical Schematic View 5 S 120HD Models 5 44 ...

Page 228: ...September 2016 Section 5 Schematics 5 46 Electrical Schematic View 6 S 120HD Models 5 45 ...

Page 229: ...Section 5 Schematics September 2016 5 47 5 48 Electrical Schematic View 7 S 120HD Models ...

Page 232: ...September 2016 Section 5 Schematics 5 50 Safety Circuit Schematic S 120HD Models 5 49 ...

Page 233: ...Section 5 Schematics September 2016 5 51 Perkins 854F 34T Engine Electrical Schematic 5 52 ...

Page 235: ...Section 5 Schematics September 2016 Part No 1268495 S 100HD S 120HD 5 53 ...

Page 236: ...September 2016 Section 5 Schematics 5 54 Perkins 854F 34T Engine Electrical Harness 5 53 ...

Page 237: ...Section 5 Schematics September 2016 5 55 Deutz TD2 9 Engine Electrical Schematic 5 56 ...

Page 240: ...September 2016 Section 5 Schematics 5 58 Deutz TD2 9 Engine Electrical Harness 5 57 ...

Page 241: ...Section 5 Schematics September 2016 5 59 Hydraulic Schematic S 100HD Models 5 60 ...

Page 248: ...September 2016 Section 5 Schematics 5 66 Hydraulic Schematic S 120HD Models 5 60 ...

Page 249: ......