3 - 40

S-100HD • S-120HD

Part No. 1268495

September 2016

Section 3 • Repair Procedures

4-3

Boom Lift Cylinder

How to Remove the Boom

Lift Cylinder

Bodily injury hazard. This

procedure requires specific repair

skills, lifting equipment and a

suitable workshop. Attempting

this procedure without these skills

and tools could result in death

or serious injury and significant

component damage. Dealer

service is strongly recommended.

Note: When removing a hose assembly or fitting,

the O-ring on the fitting and/or hose end must be

replaced and then torqued to specification during

installation.

Refer to Specifications,

Hydraulic Hose and Fitting

Torque Specifications.

1 Raise the boom until there is approximately

4 feet / 1.2 m between the turntable and boom

rest pad.

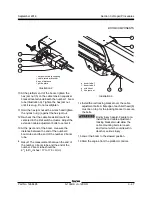

2 Attach a lifting strap from an overhead crane or

other suitable lifting device to the rod end of the

the boom lift cylinder.

3 Attach an overhead

10 ton / 9071 kg crane to

the platform end of the boom for support. Do

not lift the boom.

4 Remove the boom storage area cover retaining

fasteners. Remove the cover from the machine.

5 Place support blocks under the boom lift

cylinder.

6 Remove the pin retaining fastener from the

boom lift cylinder rod-end pivot pin. Use a

soft metal drift to remove the pin. Protect the

cylinder rod from damage.

Crushing hazard. The boom lift

cylinder may fall when the rod-end

pivot pin is removed if the boom lift

cylinder is not properly supported

by the overhead crane.

Crushing hazard. The boom

may fall when the rod-end pivot

pin is removed if the boom is

not properly supported by the

overhead crane.

7 Carefully raise the boom with the overhead

crane until the rod end of the boom lift cylinder

can be removed.

8 Carefully lower the rod end of the boom lift

cylinder down onto the support blocks.

9 Carefully raise the boom with the overhead

crane until the barrel end of the boom lift

cylinder is accessible.

10 Tag, disconnect and plug the boom lift cylinder

hydraulic hoses. Cap the fittings on the cylinder.

Bodily injury hazard. Spraying

hydraulic oil can penetrate and

burn skin. Loosen hydraulic

connections very slowly to allow

the oil pressure to dissipate

gradually. Do not allow oil to

squirt or spray.

BOOM COMPONENTS

Summary of Contents for Genie S-100HD

Page 14: ...September 2016 S 100HD S 120HD Part No 1268495 xiv This page intentionally left blank ...

Page 124: ...3 94 S 100HD S 120HD Part No 1268495 September 2016 Section 3 Repair Procedures MANIFOLDS ...

Page 126: ...3 96 S 100HD S 120HD Part No 1268495 September 2016 Section 3 Repair Procedures MANIFOLDS ...

Page 201: ...Section 5 Schematics September 2016 5 19 Electrical Schematic View 1 S 100HD Models 5 20 ...

Page 204: ...September 2016 Section 5 Schematics 5 22 Electrical Schematic View 2 S 100HD Models 5 21 ...

Page 205: ...Section 5 Schematics September 2016 5 23 Electrical Schematic View 3 S 100HD Models 5 24 ...

Page 208: ...September 2016 Section 5 Schematics 5 26 Electrical Schematic View4 S 100HD Models 5 25 ...

Page 209: ...Section 5 Schematics September 2016 5 27 Electrical Schematic View 5 S 100HD Models 5 28 ...

Page 212: ...September 2016 Section 5 Schematics 5 30 Electrical Schematic View 6 S 100HD Models 5 29 ...

Page 213: ...Section 5 Schematics September 2016 5 31 Electrical Schematic View 7 S 100HD Models 5 32 ...

Page 216: ...September 2016 Section 5 Schematics 5 34 5 33 Safety Circuit Schematic S 100HD Models ...

Page 217: ...Section 5 Schematics September 2016 5 35 5 36 Electrical Schematic View 1 S 120HD Models ...

Page 220: ...September 2016 Section 5 Schematics 5 38 Electrical Schematic View 2 S 120HD Models 5 37 ...

Page 221: ...Section 5 Schematics September 2016 5 39 Electrical Schematic View 3 S 120HD Models 5 40 ...

Page 224: ...September 2016 Section 5 Schematics 5 42 Electrical Schematic View 4 S 120HD Models 5 41 ...

Page 225: ...Section 5 Schematics September 2016 5 43 Electrical Schematic View 5 S 120HD Models 5 44 ...

Page 228: ...September 2016 Section 5 Schematics 5 46 Electrical Schematic View 6 S 120HD Models 5 45 ...

Page 229: ...Section 5 Schematics September 2016 5 47 5 48 Electrical Schematic View 7 S 120HD Models ...

Page 232: ...September 2016 Section 5 Schematics 5 50 Safety Circuit Schematic S 120HD Models 5 49 ...

Page 233: ...Section 5 Schematics September 2016 5 51 Perkins 854F 34T Engine Electrical Schematic 5 52 ...

Page 235: ...Section 5 Schematics September 2016 Part No 1268495 S 100HD S 120HD 5 53 ...

Page 236: ...September 2016 Section 5 Schematics 5 54 Perkins 854F 34T Engine Electrical Harness 5 53 ...

Page 237: ...Section 5 Schematics September 2016 5 55 Deutz TD2 9 Engine Electrical Schematic 5 56 ...

Page 240: ...September 2016 Section 5 Schematics 5 58 Deutz TD2 9 Engine Electrical Harness 5 57 ...

Page 241: ...Section 5 Schematics September 2016 5 59 Hydraulic Schematic S 100HD Models 5 60 ...

Page 248: ...September 2016 Section 5 Schematics 5 66 Hydraulic Schematic S 120HD Models 5 60 ...

Page 249: ......