December 2019

Service and Repair Manual

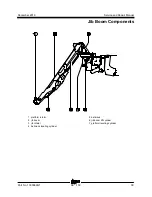

Jib Boom Components

Part No. 1300669GT

SX

™

-150

43

3-4

Jib Boom Bellcrank Angle Sensor

The jib boom bellcrank angle sensor is monitored

by the control system to keep the jib boom

bellcrank vertical and to help maintain a level

platform through boom range of motion. If a jib

boom bellcrank angle sensor is replaced, it must be

calibrated prior to machine operation. The jib boom

bellcrank angle sensor is mounted to the bellcrank

pivot pin on the engine side of the machine.

How to Calibrate the Jib Boom

Bellcrank Angle Sensor

Note: If the primary boom angle sensor has been

removed or replaced, it must to be calibrated

before the jib boom bellcrank angle sensor. Refer

to Repair Procedure,

How to Calibrate the Primary

Boom Angle Sensor

.

Note: Perform this procedure with the machine on

a firm, level surface and in the stowed position with

the axles extended.

Note: A digital level will be required to perform this

procedure.

Note: A kit is available through Genie Product

Support (Genie part number 58351GT). This kit

includes a digital level with a magnetic base and

cable harnesses.

Note: Use the following chart to identify the

description of each LCD screen control button used

in this procedure.

Plus

Minus

Previous

Enter

1 Place a digital level with a magnetic base, on

the underside of the jib bellcrank as shown in

Illustration 1.

Illustration 1

1 digital level

2 Raise the jib boom to a slightly less than

horizontal position.

3 Push in the ground controls red Emergency

Stop button to the off position. Do not turn the

key switch to the off position.

4 Open the ground control box.

5 Locate the calibration toggle switch at the top

of the ground control box. Activate calibration

mode by moving the toggle switch in the left

direction.

6 Temporarily install a control box door retaining

fastener between the door and the box to

prevent the control box door from moving the

toggle switch while calibrating the machine.

Summary of Contents for Genie SX-150

Page 105: ...December 2019 Service and Repair Manual Manifolds Part No 1300669GT SX 150 93 ...

Page 107: ...December 2019 Service and Repair Manual Manifolds Part No 1300669GT SX 150 95 ...

Page 109: ...December 2019 Service and Repair Manual Manifolds Part No 1300669GT SX 150 97 ...

Page 117: ...December 2019 Service and Repair Manual Part No 1300669GT SX 150 105 ...

Page 119: ...December 2019 Service and Repair Manual Part No 1300669GT SX 150 107 ...

Page 122: ...Service and Repair Manual December 2019 Manifolds 110 SX 150 Part No 1300669GT ...

Page 124: ...Service and Repair Manual December 2019 Manifolds 112 SX 150 Part No 1300669GT ...

Page 229: ...December 2019 Service and Repair Manual 217 Control Circuits Horn ...

Page 230: ...Service and Repair Manual December 2019 218 SX 150 Part No 1300669GT Control Circuits Horn ...

Page 231: ...December 2019 Service and Repair Manual Part No 1300669GT SX 150 219 Control Circuits Power ...

Page 232: ...Service and Repair Manual December 2019 220 Control Circuits Power ...

Page 233: ...December 2019 Service and Repair Manual 221 Control Circuits Can Bus ...

Page 234: ...Service and Repair Manual December 2019 222 SX 150 Part No 1300669GT Control Circuits Can Bus ...

Page 236: ...Service and Repair Manual December 2019 224 Control Circuits Deutz TD2011L04i Engine ...

Page 237: ...December 2019 Service and Repair Manual 225 Control Circuits Deutz TD 2 9 L4Engine ...

Page 240: ...Service and Repair Manual December 2019 228 Control Circuits Perkins 1104D 44T Engine ...

Page 241: ...December 2019 Service and Repair Manual 229 Control Circuits Perkins 854F 34T Engine ...

Page 244: ...Service and Repair Manual December 2019 232 Control Circuits Axle Extend Retract ...

Page 245: ...December 2019 Service and Repair Manual 233 Control Circuits Steering ...

Page 247: ...December 2019 Service and Repair Manual Part No 1300669GT SX 150 235 Control Circuits Propel ...

Page 248: ...Service and Repair Manual December 2019 236 Control Circuits Propel ...

Page 249: ...December 2019 Service and Repair Manual 237 Control Circuits Turntable Rotate ...

Page 252: ...Service and Repair Manual December 2019 240 Control Circuits Boom Up Down ...

Page 253: ...December 2019 Service and Repair Manual 241 Control Circuits Boom Extend Retract ...

Page 261: ...December 2019 Service and Repair Manual 249 Control Circuits Recovery PLD ...

Page 264: ...Service and Repair Manual December 2019 252 Control Circuits Telematics ...

Page 265: ...December 2019 Service and Repair Manual 253 Generator Receptacle Wiring ANSI CSA ...

Page 268: ...Service and Repair Manual December 2019 256 Generator Receptacle Wiring CE ...

Page 269: ...December 2019 Service and Repair Manual 257 Perkins 1104D 44T Engine Electrical Schematic ...

Page 272: ...Service and Repair Manual December 2019 260 Perkins 854F 34T Engine Electrical Schematic ...

Page 273: ...December 2019 Service and Repair Manual 261 Perkins 854F 34T Engine Harness ...

Page 276: ...Service and Repair Manual December 2019 264 Deutz TD 2 9 L4 Engine Electrical Schematic ...

Page 277: ...December 2019 Service and Repair Manual 265 Deutz TD 2 9 L4 Engine Harness ...

Page 279: ...December 2019 Service and Repair Manual 267 Hydraulic Schematic ...

Page 280: ...Service and Repair Manual December 2019 268 Hydraulic Schematic ...

Page 282: ......