October 2021

Service and Repair Manual

Engines

Part No. 1268515GT

Z

®

-34/22 Bi-Energy

41

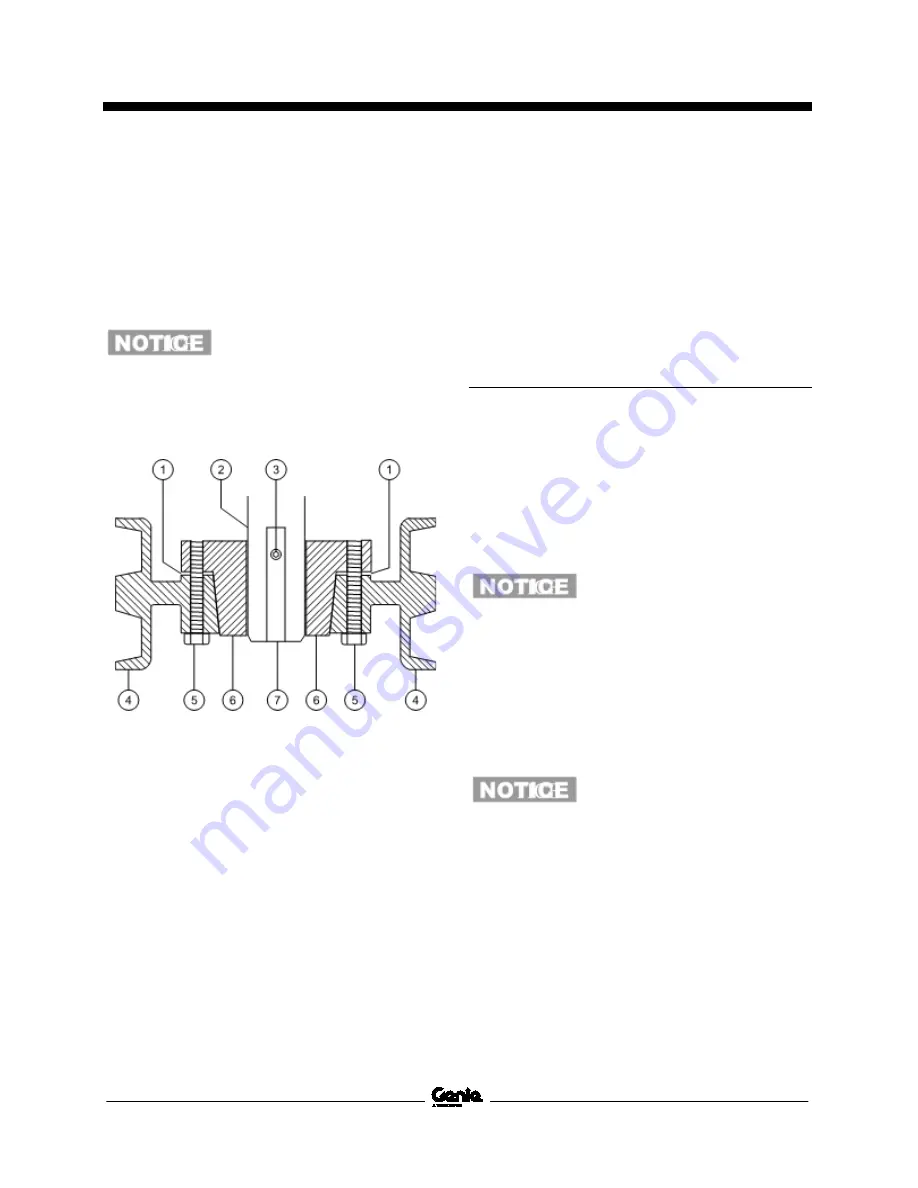

3 Tighten the set screw on the pulley bushing

hand tight.

4 Slide the engine pulley onto the pulley

bushing.

5 Install the pulley mounting bolts and tighten

them to specification. Refer to Specifications,

Generator Specifications

.

Component damage hazard. Do

not overtighten the pulley

mounting bolts. There must be a

gap visible between the engine

drive pulley and the pulley

bushing.

1 gap

2 shaft

3 set screw

4 engine drive pulley

5 engine drive pulley bolt

6 shaft bushing

7 woodruff key

6 Check the alignment between the engine

drive pulley and the generator pulley using a

straightedge. Refer to Specifications,

Generator.

Note: If the pulley alignment is not within

specification, remove the engine pulley and repeat

steps 2 through 6. Refer to Repair Procedure,

How

to Remove the Engine Drive Pulley.

Coolant Temperature and Oil

Pressure Switches

The engine coolant temperature switch is a

normally open switch. The switch contacts close at

approximately 225°F / 107°C. If the coolant

temperature rises above the switch point, the

switch contacts close and the engine will shut off

to prevent damage. The engine will not start until

the temperature drops below the switch point. An

over- temperature indicator light at the ground

controls should turn on when the switch closes.

Component damage hazard.Do

not crank the engine with the

over-temperature light on.

The engine oil switch is a normally closed switch.

The switch contacts open at approximately 7 psi /

0.48 bar. If the oil pressure drops below the switch

point, the contacts open and the engine will shut

off to prevent damage. A low oil pressure indicator

light at the ground controls should turn on when

the switch opens.

Component damage hazard.Do

not crank the engine with the low

oil pressure light on.

Summary of Contents for Genie Z-34/22

Page 63: ...October 2021 Service and Repair Manual Manifolds Part No 1268515GT Z 34 22 Bi Energy 51 ...

Page 89: ...October 2021 Service and Repair Manual 77 Electrical Schematic ANSI CSA from SN Z34F 12066 ...

Page 92: ...Service and Repair Manual October 2021 80 Electrical Schematic ANSI CSA from SN Z34F 12066 ...

Page 97: ...October 2021 Service and Repair Manual 85 PBOX Wiring Diagram ANSI CSA from SN Z3414 9686 ...

Page 103: ...October 2021 Service and Repair Manual 91 Electrical Schematic CE AS from SN Z34F 12066 ...

Page 106: ...Service and Repair Manual October 2021 94 Electrical Schematic CE AS from SN Z34F 12066 ...

Page 114: ...Service and Repair Manual October 2021 102 Power Cable Wiring Diagram from SN Z3414 9686 ...

Page 115: ...October 2021 Service and Repair Manual 103 Drive Contactor Panel Wiring Diagram ...

Page 118: ...Service and Repair Manual October 2021 106 Manifold and Limit Switch Wiring Diagram ...

Page 119: ...October 2021 Service and Repair Manual 107 LVI BCI Option Wiring Diagram ...

Page 122: ...Service and Repair Manual October 2021 110 Charger Interlock Option ...

Page 123: ...October 2021 Service and Repair Manual 111 Engine Wiring Diagram ...

Page 126: ...Service and Repair Manual October 2021 114 Contact Alarm Option from SN Z34F 12066 ...

Page 127: ...October 2021 Service and Repair Manual 115 Fuel Level Sensor Option from SN Z34F 12066 ...

Page 129: ...October 2021 Service and Repair Manual 117 Hydraulic Schematic ...

Page 131: ......