December 2018

Service and Repair Manual

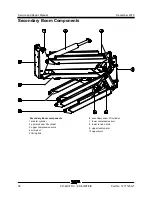

Primary Boom Components

Part No. 1271125GT

Z®-60/37 DC • Z®-60

/37 FE

33

4-3

Primary Boom Lift Cylinder

The primary boom lift cylinder raises and lowers the

primary boom. The primary boom lift cylinder is

equipped with a counterbalance valve to prevent

movement in the event of a hydraulic line failure.

How to Remove the Primary

Boom Lift Cylinder

Bodily injury hazard. This

procedure requires specific repair

skills, lifting equipment and a

suitable workshop. Attempting

this procedure without these skills

and tools could result in death or

serious injury and significant

component damage. Dealer

service is strongly recommended.

Note: When removing a hose assembly or fitting,

the O-ring (if equipped) on the fitting and/or hose

end must be replaced. All connections must be

torqued to specification during installation. Refer to

Specifications,

Hydraulic Hose and Fitting Torque

Specifications.

1

Raise the primary boom to a horizontal

position.

2

Raise the secondary boom until the upper

secondary arm is above the compression

arms.

3

Place a block across both compression arms.

Lower the secondary boom until it just rest on

the block. Do not rest the entire weight of the

boom on the block.

4

Attach a 5 ton / 5000 kg overhead crane to the

primary boom for support.

5

Raise the primary boom with the overhead

crane slightly to take the pressure off the

primary boom lift cylinder pivot pins.

6

Support the rod end and the barrel end of the

primary boom lift cylinder with a second

overhead crane or similar lifting device.

7

Tag, disconnect and plug the primary boom lift

cylinder hydraulic hoses. Cap the fittings on

the cylinder.

Bodily injury hazard. Spraying

hydraulic oil can penetrate and

burn skin. Loosen hydraulic

connections very slowly to allow

the oil pressure to dissipate

gradually. Do not allow oil to

squirt or spray.

8

Remove the retaining fasteners from the

primary boom lift cylinder rod-end pivot pin.

Use a soft metal drift to remove the pin.

Crushing hazard. The primary

boom will fall if not properly

supported when the primary

boom rod-end pivot pin is

removed.

9

Place a support block across the upper arm

under the primary boom lift cylinder.

10 Lower the rod end of the lift cylinder onto the

block. Protect the cylinder rod from damage.

Crushing hazard. The primary

boom lift cylinder could become

unbalanced and fall if not

properly supported by the lifting

device.

11 Remove the primary boom lift cylinder

barrel-end pivot pin snap rings.

12 Use a soft metal drift to remove the pin.

Carefully remove the primary boom lift cylinder

from the machine.

Crushing hazard. The lift cylinder

could become unbalanced and

fall if not properly supported and

secured to the lifting device.

Summary of Contents for Genie Z-60 DC

Page 54: ...Service and Repair Manual December 2018 Manifolds 44 Z 60 37 DC Z 60 37 FE Part No 1271125GT ...

Page 56: ...Service and Repair Manual December 2018 Manifolds 46 Z 60 37 DC Z 60 37 FE Part No 1271125GT ...

Page 107: ...December 2018 Service and Repair Manual 97 Wiring Diagram Options ...

Page 110: ...Service and Repair Manual December 2018 100 Schematics Options 4WD DC and FE Models ...

Page 111: ...December 2018 Service and Repair Manual 101 Power Cable Wiring Diagram ...

Page 113: ...December 2018 Service and Repair Manual 103 Hydraulic Schematic DC and FE Models ...

Page 115: ...December 2018 Service and Repair Manual 105 Electrical Schematic DC FE Models ...

Page 118: ...Service and Repair Manual December 2018 108 Electrical Schematic DC FE Models ...

Page 120: ...Service and Repair Manual December 2018 110 Electrical Schematic DC FE Models ...

Page 125: ......