Chapter Overview

This chapter provides information on inspection, disas-

sembly and assembly of major hydraulic components.

Personal Safety

Improper or incomplete maintenance/repair of a Compact

Track Loader can be dangerous and may result in machine

damage, injury or death.

Do not attempt to perform any type of repair or maintenance

on a Compact Track Loader until you have read and fully

understood the information in this manual. Refer to the

Operation and Maintenance manual for instructions regard-

ing proper machine operation techniques before operating

any Compact Track Loader.

Prior to performing any type of service work on a Compact

Track Loader, read and understand Chapter 1 (Product

Safety) for personal safety information.

When servicing any hydraulic component, keep in

mind that any scratches or damage that can be felt

with a fingernail on surfaces that parts move, slide, roll

or rotate upon indicate a need for part replacement.

Hydraulic components must be kept extremely clean to

ensure proper function and service life. Do not assem-

ble any components that have not been inspected for

damage and thoroughly cleaned prior to assembly.

The hydraulic system fluid should be changed fol-

lowing any hydraulic component service according

to the procedure described on page 4-16.

Disassembly & Assembly

Disassembly and assembly procedures are provided

for the following components:

•

Hydraulic Cylinders

•

Lift Arm Control Valve

•

Drive Pump Reliefs

•

Drive Pump Solenoids/Spools

•

Auxiliary Pump

Note:

Procedures are provided for only those components

listed above. However, exploded parts diagrams exist in the

PT-100G parts manual to serve as visual aids in the assem-

bly and disassembly of other system components.

Hydraulic Cylinder

Disassembly

1.

With machine off and cool and with hydraulic actu-

ators relaxed, disconnect and cap hoses from the

cylinder(s) to be serviced.

Note:

When servicing cylinders, the attached components

must be supported in a manner that allows the cylinders to

be safely removed and installed. (lift arms & quick attach)

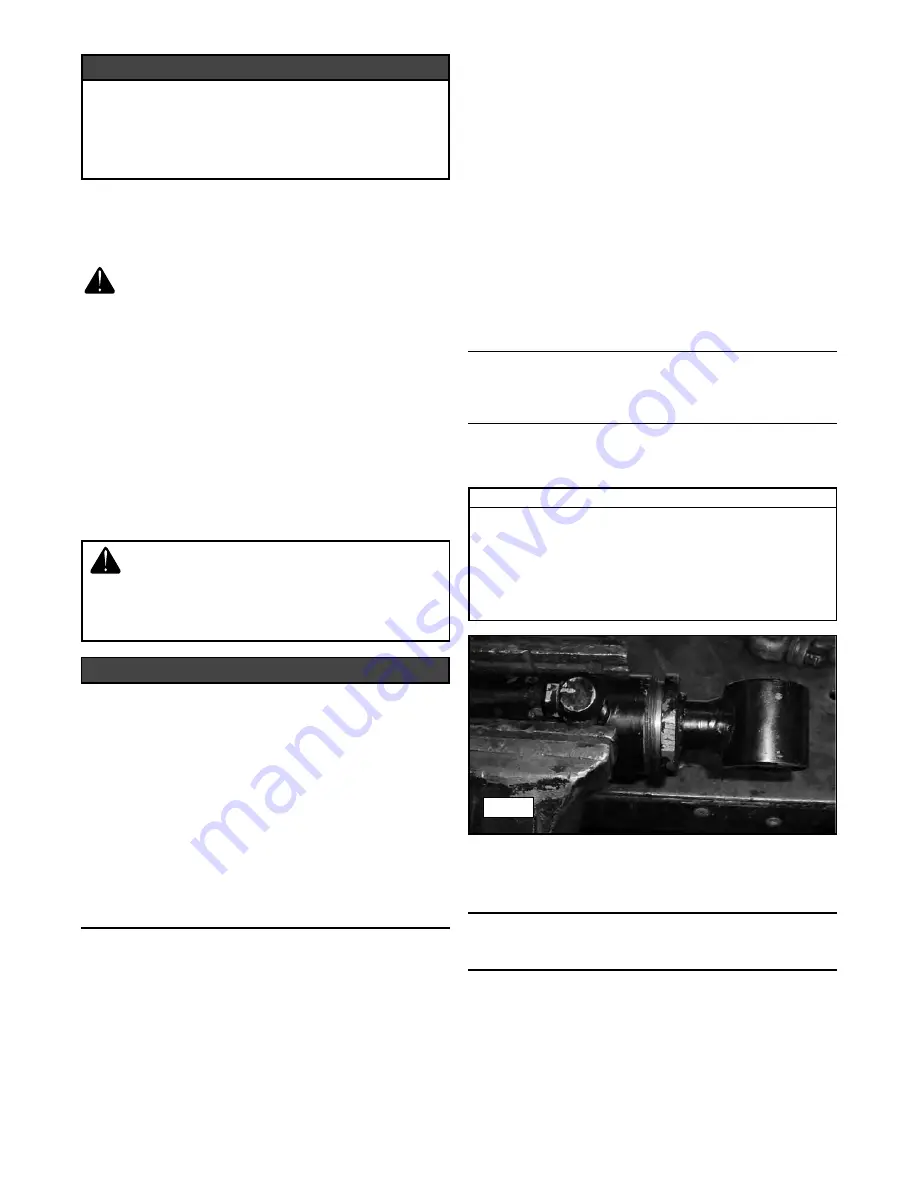

2.

Remove the cylinder(s) and secure it in a bench

vise to aid in disassembly. (figure 16-1)

3.

Place a suitable catch container beneath the rod

end of the cylinder to catch any hydraulic oil that

may leak out upon disassembly.

Required Tools

Bench Vise

Pipe Wrench

Socket or Impact Wrench

Screwdriver (blade type)

Rubber or Dead Blow Hammer

Small Pry Bar

16-1

NOTICE

Disassembly of hydraulic components should only be performed

by factory trained personnel experienced in the disassembly

and repair of hydraulic components. Components should not be

serviced during the warranty period without written instruction

from the Terex service department. Component disassembly

during this period may void the manufacturer’s warranty.

NOTICE

When servicing any hydraulic component,

make sure the machine is off and cool and

that all of the hydraulic actuators are relaxed

prior to disconnecting or removing any compo-

nent from the system.

16-1

16. Hydraulic Component

Service Procedures

Summary of Contents for PT100G Forestry

Page 1: ...PT 100G PT 100G Forestry Part Number 2076 286 Printed 8 10 Service Manual Compact Track Loader...

Page 2: ......

Page 6: ......

Page 12: ......

Page 14: ......

Page 22: ......

Page 40: ......

Page 52: ......

Page 62: ......

Page 66: ......

Page 80: ......

Page 98: ......

Page 102: ......

Page 116: ......

Page 136: ......

Page 138: ......

Page 140: ......

Page 141: ......