Service and Repair Manual

December 2019

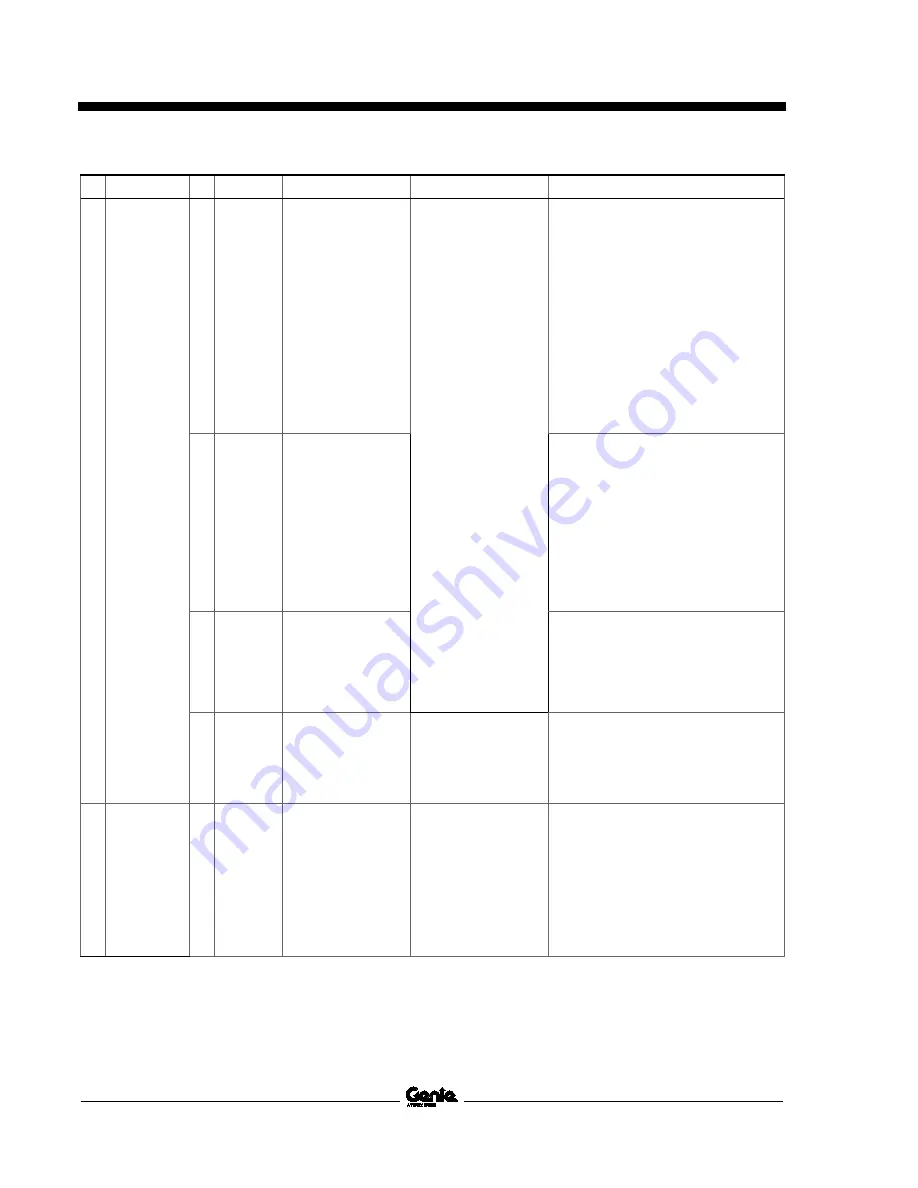

Control System Fault Codes

80

S

®

-60 J

Part No. 1285305GT

ID Component ID Name

Cause

Effect

Solution

24 Pri Boom

Angle

13 Not

detected

No CAN messages

have been received

by the TCON from

the Angle Sensor.

Machine limited to

recovery functions

* Verify sensor power P85PWR (GR,

TCON J6-7) is at 12 V while the

system is running.

* Verify the sensor is receiving power.

Unplug the sensor and verify 12 V

across pins 2 (+) and 1 (-) on the

harness connector.

* Verify the CAN bus wiring. With the

sensor still unplugged, measure

resistance across harness connector

pins 3 and 4. If resistance is not

between 55 and 65 ohms, check CAN

wire harnesses.

* Replace sensor if necessary.

14 Cross

check

failed

Boom stowed

crosscheck switch

value not as

expected

*Verify that with the boom stowed

C68LS (BL, TCON J7-3) is 12V and

that the boom is making contact with

the LST3S limit switch arm.

*Verify that with the boom above

12 degrees C68LS (BL, TCON J7-3)

is 0V and that the boom is not making

contact with the LST3S limit switch

arm.

*Check LST3S limit switch for physical

damage.

17 Not

calibrated

Sensor has been

replaced and

requires calibration,

or calibration in

memory has been

erased.

Run the boom angle calibration

process and verify fault is no longer

active.

19 Value out

of

expected

range

Min or max boom

angle out of

expected range.

Machine limited to

recovery functions

* Calibrate boom angle snesor.

* Check boom angle sensor mount,

ensure all fasteners are tightened to

spec.

* Replace sensor if issue persists.

25 Cable

tension

21 Fault

Boom cable tension

limit switch LSB2S

indicates that the

tension is loose on

the boom cables.

Boom Up and Extend

functions will not

operate.

* Return boom to stowed position as

quickly as possible.

* Verify both boom cables are properly

tensioned and that LST3S is properly

centered in the bracket.

* Verify LSB2S (C59CNK, BL/WH,

TCON J7-5) operates properly. Signal

should normally by 12 V. If cable

tension is loose, signal should be 0 V.

Summary of Contents for S-60 J

Page 67: ...December 2019 Service and Repair Manual Manifolds Part No 1285305GT S 60 J 55 ...

Page 69: ...December 2019 Service and Repair Manual Manifolds Part No 1285305GT S 60 J 57 ...

Page 77: ...December 2019 Service and Repair Manual Manifolds Part No 1285305GT S 60 J 65 ...

Page 115: ...December 2019 Service and Repair Manual 103 Electrical Schematic Generator Options ...

Page 118: ...Service and Repair Manual December 2019 106 Electrical Schematic Positive Air Shutdown ...

Page 119: ...December 2019 Service and Repair Manual 107 Electrical Schematic Turntable Controller ...

Page 122: ...Service and Repair Manual December 2019 110 Electrical Schematic Platform Controller ...

Page 123: ...December 2019 Service and Repair Manual 111 Electrical Schematic Kubota D1803 ...

Page 126: ...Service and Repair Manual December 2019 114 Electrical Schematic Kubota D1105 ...

Page 127: ...December 2019 Service and Repair Manual 115 Electrical Schematic Deutz D2011 ...

Page 129: ...December 2019 Service and Repair Manual Part No 1285305GT S 60 J 117 Hydraulic Schematic ...

Page 131: ......