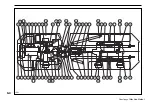

8-7

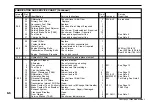

Interval Ref.

No. of

Service

Hours

Points

Identification

Service Instructions

Points

Lubricant

Quantities

1

Engine

Steam clean

1

7

Radiator and Cooling System

Drain, flush and refill.

Coolant

See Page 13

21/22

Drivelines (Low Maintenance) Check for leaks and damage.

-

-

See Page 12

27

Articulation Pivot Nut

Check torque

1

1 425 Nm (1 050 lb ft)

2 000

36

Fuel Cooler

Strip, clean and inspect

1

37

Charge Air Cooler

Strip, clean and inspect

1

18

Drive Belts

Replace all belts.

40

OCDB Filter

Replace.

2 250

3

Hydraulic Tank

Drain oil and refill.

1

HO

See Page 13

-

Suction Screens and Strainers Clean.

2

4 000

-

Thermostats and Seals

Replace.

6 000

34

Engine Oil Cooler

Strip, clean and inspect.

1

35

Transmission Oil Cooler

Strip, clean and inspect.

1

Notes on 'Lubrication and Service Chart'

Note -

Capacities given are approximate - work to dipstick,

sight gauges or level plugs.

Note 1 -

Lubricate slowly until excess lube is seen.

Note 2 -

Remove plugs and fit lube fittings. Lubricate slowly

until excess lube is seen. Remove fittings and refit

plugs.

Note 3 -

Check with the engine idling and the transmission at

its normal operating temperature.

Note 4 -

When refilling centre axle ensure that 3rd differential

unit is primed with 1 litre (1.75 UK pints) of oil before

filling drive head.

Note 5 -

Remove plug from port on underside of oscillation

hub. Plug is removed to drain the cavity of any oil

that enters the cavity when filling. Remove grommet

and level plug on side of oscillation hub. Add oil if

required. Refit all plugs.

Note 6 -

Clean radiator and cooler fins more often when

operating under extremely dusty conditions.

EO -

Engine Oil. Refer to 'Recommended Lubricants'.

* -

Refer to chart under 'Recommended Lubricants'.

HO -

Hydraulic Oil. Refer to 'Recommended Lubricants'.

EPL -

Extreme Pressure Lubricant specification

MIL-L-2105 D.

EP, NLGI -

Extreme Pressure, Lithium No. 2 Grease (which may,

or may not, contain Molybdenum).

*EP, NLGI - Extreme Pressure, Lithium No. 2 Grease (without

Molybdenum).

EMS19057 - Extreme Pressure, Lithium Complex Grease. Refer to

'Recommended Lubricants'.

HTO -

Hydraulic Transmission Oil. Refer to 'Recommended

Lubricants'.

LZ -

Lubrizol 6178

PAG Oil -

Polyalklene Glycol (PAG) Compressor Lubricating Oil -

Low Viscosity (ISO46).

LUBRICATION AND SERVICE CHART (Continued)

Summary of Contents for TA35

Page 1: ...Operation Safety Maintenance TA35 TA40 Courtesy of Machine Market...

Page 4: ...Courtesy of Machine Market...

Page 17: ...2 1 2 Safety Precautions Courtesy of Machine Market...

Page 34: ...2 18 Courtesy of Machine Market...

Page 35: ...3 1 3 Controls and Operating Courtesy of Machine Market...

Page 76: ...3 42 Courtesy of Machine Market...

Page 77: ...4 1 4 Operating The Truck Courtesy of Machine Market...

Page 93: ...5 1 5 Working the Truck Courtesy of Machine Market...

Page 101: ...6 1 6 Roading Courtesy of Machine Market...

Page 105: ...7 1 7 Moving Disabled Truck Courtesy of Machine Market...

Page 108: ...7 4 Courtesy of Machine Market...

Page 109: ...8 1 8 Lubrication and Servicing Courtesy of Machine Market...

Page 124: ...8 16 Courtesy of Machine Market...

Page 125: ...9 1 9 Technical Data Courtesy of Machine Market...

Page 132: ...9 8 Courtesy of Machine Market...

Page 133: ...9 9 TA40 Technical Data On Following Page Courtesy of Machine Market...

Page 140: ...9 16 Courtesy of Machine Market...

Page 141: ...10 Symbol Identification Courtesy of Machine Market...

Page 147: ...10 7 Notes Courtesy of Machine Market...

Page 148: ...10 8 NOTES Courtesy of Machine Market...

Page 149: ...10 9 NOTES Courtesy of Machine Market...

Page 150: ...10 10 NOTES Powered by TCPDF www tcpdf org Courtesy of Machine Market...