9-12

AXLES

Three axles in permanent all-wheel drive with differential

coupling between each axle to prevent driveline wind-up.

Heavy duty axles with fully-floating axle shafts and

outboard planetary gearing.

Automatic limited slip differentials in each axle. Leading

rear axle incorporates a through-drive differential to

transmit drive to the rearmost axle. Locking of this

differential is actuated simultaneously with the

transmission output differential lock.

Ratios:

Differential ............................................................... 4.86:1

Planetary .................................................................. 4.94:1

Total Reduction ....................................................... 24.0:1

SUSPENSION

Front: Axle located by a leading A-frame permitting both

vertical movement and oscillation. Rubber cone

suspension medium with heavy duty hydraulic dampers.

Axle Vertical Travel ................................ 105 mm (4.2 in)

Rear: Each axle is coupled to the frame by three rubber-

bushed links with lateral restraint by a transverse link.

Pivoting inter-axle balance beams equalise load on each

rear axle. Suspension movement is cushioned by rubber/

metal laminated compression units between each axle

and underside of balance beam ends. Pivot points on

rear suspension linkages are rubber-bushed and

maintenance-free.

Axle Vertical Travel ............................ ± 115 mm (± 4.5 in)

Axle Oscillation ............................................................ ± 9°

BRAKES

Full hydraulic braking system with enclosed, forced oil-

cooled multiple discs on each wheel. Independent circuits

for front and rear brake systems. Warning lights and

audible alarm indicate low brake system pressure. Brake

system conforms to ISO 3450, SAE J1473.

Actuating Pressure ....... 138 ± 6.2 bar (2 000 ± 90 lbf/in²)

Pump Type ................................................ Triple stage gear

Capacity at 2 200 rev/min .... 2.02 litre/s (32 US gal/min)

combined

Braking surface (tractor) .. 802837 mm

2

(1244.4 in

2

)/brake

Braking surface (trailer) ...... 535225 mm

2

(829.6 in

2

)/brake

Parking:

Spring-applied, hydraulic-released disc on

rear driveline.

Emergency: Automatic application of driveline brake

should pressure fall in main brake hydraulic

system. Service brakes may also be applied

using the parking-emergency brake control.

Retardation: Hydraulic retarder integral with transmission.

Summary of Contents for TA35

Page 1: ...Operation Safety Maintenance TA35 TA40 Courtesy of Machine Market...

Page 4: ...Courtesy of Machine Market...

Page 17: ...2 1 2 Safety Precautions Courtesy of Machine Market...

Page 34: ...2 18 Courtesy of Machine Market...

Page 35: ...3 1 3 Controls and Operating Courtesy of Machine Market...

Page 76: ...3 42 Courtesy of Machine Market...

Page 77: ...4 1 4 Operating The Truck Courtesy of Machine Market...

Page 93: ...5 1 5 Working the Truck Courtesy of Machine Market...

Page 101: ...6 1 6 Roading Courtesy of Machine Market...

Page 105: ...7 1 7 Moving Disabled Truck Courtesy of Machine Market...

Page 108: ...7 4 Courtesy of Machine Market...

Page 109: ...8 1 8 Lubrication and Servicing Courtesy of Machine Market...

Page 124: ...8 16 Courtesy of Machine Market...

Page 125: ...9 1 9 Technical Data Courtesy of Machine Market...

Page 132: ...9 8 Courtesy of Machine Market...

Page 133: ...9 9 TA40 Technical Data On Following Page Courtesy of Machine Market...

Page 140: ...9 16 Courtesy of Machine Market...

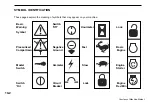

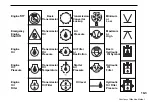

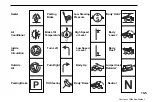

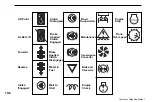

Page 141: ...10 Symbol Identification Courtesy of Machine Market...

Page 147: ...10 7 Notes Courtesy of Machine Market...

Page 148: ...10 8 NOTES Courtesy of Machine Market...

Page 149: ...10 9 NOTES Courtesy of Machine Market...

Page 150: ...10 10 NOTES Powered by TCPDF www tcpdf org Courtesy of Machine Market...