Working the Machine

5-5

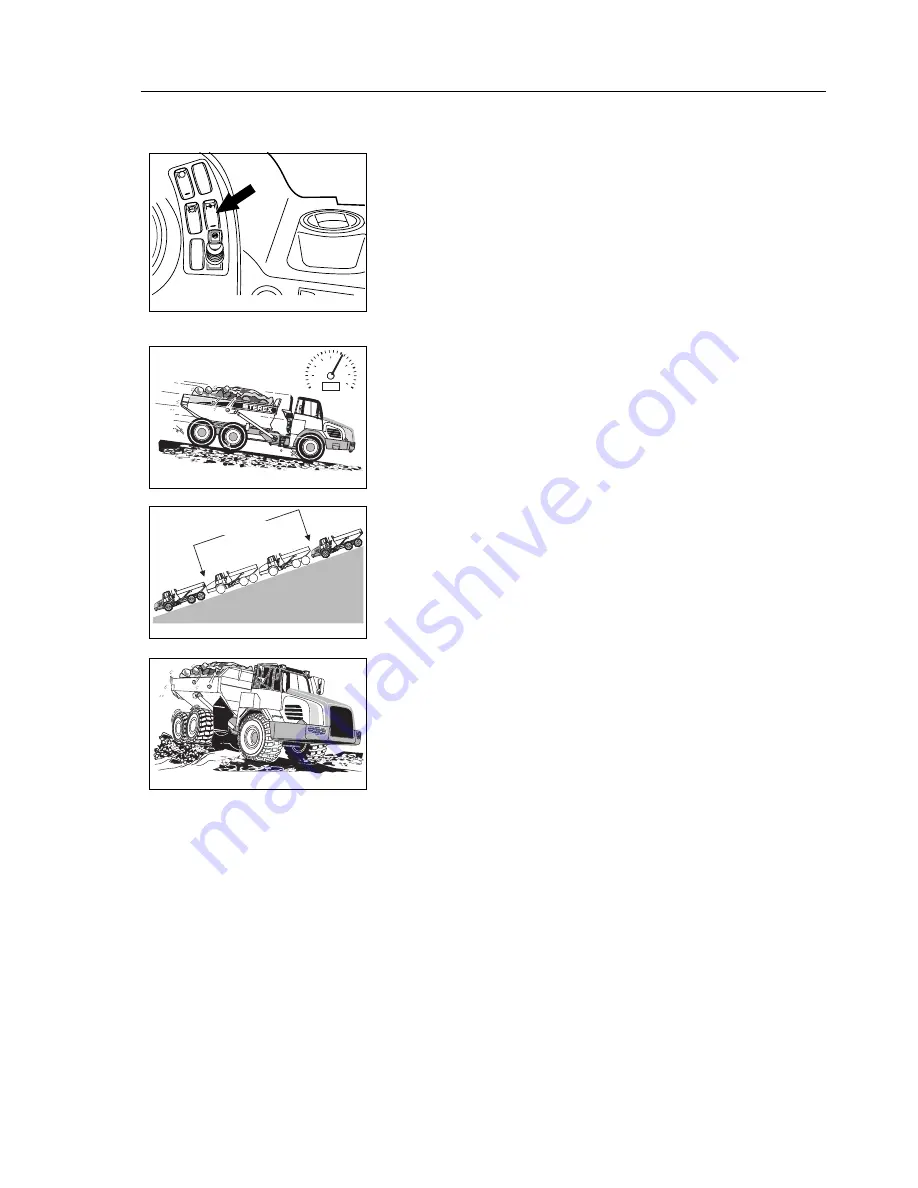

Hauling

While travelling the haul road, always maintain a safe speed for the

haul road conditions and grades. Never allow the machine to move or

coast with the transmission in 'NEUTRAL'!

When approaching or encountering extremely soft or slippery

conditions, stop the machine and engage the differential locks. Do not

engage the differential locks when the machine is moving or wheels

are spinning. Disengage the locks as soon as conditions return to

normal.

When approaching downgrades, select the proper transmission gear

range and use the retarder and service brakes as required to

maintain safe descent speed, without over-speeding the engine, or

gaining excess travel speed. Generally, the transmission range

required for ascending is also correct for descending a grade.

Always remain a safe distance behind the machine ahead,

particularly on downgrades. A good rule-of-thumb to follow is to allow

two truck-lengths between machines for each 16 km/h (10 mile/h) of

travel speed under normal operating conditions. Under adverse

conditions, allow more room for safe operation. On jobs on which

minimum distance between machines is specified for the haul road,

be sure to observe the regulations at all times. Such regulations are

established for the safety of everyone on the job.

Pay attention to haul road conditions to avoid rocks, holes, or other

obstacles. Such obstacles not only present hazards to safe operation,

but can needlessly damage tyres and suspensions if not avoided.

Driving On Soft Or Slippery Conditions

HI

LO

MOT00310

2030 Maintain Safe Speeds

10

10

20

30

40

50

60

70

80

km/h

20

30

40

mph

50

0

0000000

0000

2031 Safety First

TWO MINIMUM

2032 Avoid Obstacles

Summary of Contents for TA400

Page 2: ...This page is intentionally left blank ...

Page 4: ...This page is intentionally left blank ...

Page 6: ...This page is intentionally left blank ...

Page 8: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 18: ...This Page is Intentionally Left Blank ...

Page 20: ...This Page is Intentionally Left Blank ...

Page 25: ...Safety 2 1 2 Safety ...

Page 26: ...Safety 2 2 This Page is Intentionally Left Blank ...

Page 52: ...Safety 2 28 This Page is Intentionally Left Blank ...

Page 53: ...Controls and Operating 3 1 3 Controls and Operating ...

Page 54: ...Controls and Operating 3 2 This Page is Intentionally Left Blank ...

Page 56: ...Controls and Operating 3 4 FUSE RELAY BOX ...

Page 109: ...Operating the Machine 4 1 4 Operating the Machine ...

Page 110: ...Operating the Machine 4 2 This Page is Intentionally Left Blank ...

Page 124: ...Operating the Machine 4 16 This Page is Intentionally Left Blank ...

Page 125: ...Working the Machine 5 1 5 Working the Machine ...

Page 126: ...Working the Machine 5 2 This Page is Intentionally Left Blank ...

Page 132: ...Working the Machine 5 8 This Page is Intentionally Left Blank ...

Page 133: ...Roading 6 1 6 Roading ...

Page 134: ...Roading 6 2 This Page is Intentionally Left Blank ...

Page 137: ...Moving a Disabled Machine 7 1 7 Moving a Disabled Machine ...

Page 138: ...Moving a Disabled Machine 7 2 This Page is Intentionally Left Blank ...

Page 140: ...Moving a Disabled Machine 7 4 This Page is Intentionally Left Blank ...

Page 141: ...Lubrication and Servicing 8 1 8 Lubrication and Servicing ...

Page 142: ...Lubrication and Servicing 8 2 This page is intentionally left blank ...

Page 160: ...Lubrication and Servicing 8 20 This page is intentionally left blank ...

Page 161: ...Technical Data 9 1 9 Technical Data ...

Page 162: ...Technical Data 9 2 This Page is Intentionally Left Blank ...

Page 169: ...Symbol Identification 10 1 10 Symbol Identification ...

Page 170: ...Symbol Identification 10 2 This Page is Intentionally Left Blank ...

Page 175: ...Symbol Identification 10 7 NOTES ...

Page 176: ...Symbol Identification 10 8 NOTES ...

Page 177: ...Symbol Identification 10 9 NOTES ...