2 Safety and accident prevention

12

TW85

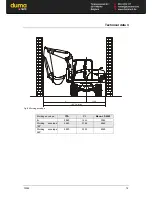

2.16 Crane operations

Load hook applications are the hoisting,

transporting and lowering of loads with the aid of a

fixing device (rope, chain, etc.), whereby the

assistance of personnel is required to attach and

release the load. Such work covers e.g. the lifting

and lowering of pipes, tubbing rings or containers.

Earth moving equipment may only be operated in

the context of using lifting gear if it is equipped and

approved for such work.

Earth moving equipment may only be used for

lifting gear applications if it is equipped with the

following safety devices:

•

Secure attachment of loading implements

•

Table of carrying capacity

•

Overload warning device

•

Hose-rupture safety valve on boom cylinder

If earth-moving machines are used for load hook

applications, personnel attaching loads is only to

approach the boom from the side and with the

machine operator’s permission. The machine

operator is only to give his permission if the earth-

moving machine is standing still and the work

equipment is not in motion.

Personnel guiding the machine and attaching

loads must always remain in the machine

operator’s field of vision.

Only use certified fixing devices (ropes, chains,

shackles) which are of adequate dimensions.

Protective gloves must always be worn when

working with fixing devices.

Loads may only be fastened which do not exceed

the lifting capacities of the machine and the lifting

gear.

Loads may only be fastened at the load hook

provided for this purpose.

Loads must be attached in such a way that they

cannot slip or fall out.

Do not carry loads over persons.

Loads must be carried as close to the ground as

possible and be prevented from swinging.

Earth-moving machines may only move with an

attached load if the path of travel is fairly level and

if the machine operator’s view of the driving zone is

guaranteed.

2.17 Change of work attachments,

maintenance, repair

Earth-moving machines shall only be converted,

maintained or serviced under the guidance of a

suitable person designated by the plant operator

and following the manufacturer’s Operating

Instructions.

After every change of work attachments, the driver

must convince himself that the quick-attach system

is correctly fastened and locked.

Work on e.g.

•

brake

systems,

•

steering

systems,

•

hydraulic

and

•

electric

systems

of the machine is only to be carried out by expert

personnel specially trained in these areas.

Stability must be ensured during all type of work on

the machine at all times.

The work equipment must be secured against

movement by lowering it to the ground or

equivalent measures, e.g. cylinder supports,

trestles. With the engine running, the unprotected

articulation range of articulated loaders shall not be

entered.

When jacking up earth-moving machines, jacking

devices must be positioned so that they cannot

slip. Jacks must be positioned and applied

absolutely straight, without tilting.

Raised earth-moving machines must be supported

by suitable structures such as crosswise stacks of

planks, square timbers or steel trusses.

Summary of Contents for TW85

Page 6: ...Table of contents TW85...

Page 112: ...7 Maintenance and care 106 TW85...

Page 125: ...Powered by TCPDF www tcpdf org...