Document 57.4400.7200 - 1

st

Edition 03/2005

INDEX

ii

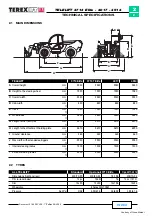

TELELIFT 3713 Elite - 4017 - 4514

INTRODUCTION

DESCRIPTION OF THE MACHINE OPERATION

The source of mechanical energy of this machine is a

Perkins turbo-compressed diesel engine

(pos. 1)

, model

1104C-44T, which supplies 74.5 kW at 2300 rev/min

and with a max torque of 412 Nm at 1400 rev/min.

On the flywheel side of the engine, and connected to

this engine by a Technodrive coupler with elastic joint

and with a 1-to-1 ratio, there is Bosch-Rexroth closed-

loop pump for hydrostatic drives, model A4VG71

(pos.

2)

with adjustment valve of DA type. The max

displacement of this swashplate pump is 71 cm

3

and

the max calibration pressure is 420 bar. This pump is

used to supply hydraulic power under form of pressure

and flow rate which is then used for moving the machine.

On the through-shaft of such drive pump there is a

Casappa open-loop gear pump (with fixed

displacement)

(pos. 3)

with priority valve integrated in

the housing. The displacement of this pump is 43 cm

3

.

Its function is to provide hydraulic power, under form of

pressure and flow rate, to the steering cylinder of the

machine (priority side) and to the telescopic boom

movement cylinder (secondary side).

The assembly of the two pumps involves they have a

rotation velocity equal to the speed of the diesel engine.

A third Casappa open-loop gear pump (with fixed

displacement)

(pos. 4)

with a displacement of 25 cm

3

,

is installed on the PTO of the engine located to the

distribution side. This pump feeds the servo-assisted

braking system

(pos. 24)

, the control block operating

the outriggers and the sway function

(pos. 28)

and the

cooling fan

(pos. 34)

of the heat exchanger

(pos. 33)

used to cool down the diesel engine and the hydraulic

circuit.

The suction lines of the open-loop pumps

(pos. 3)

and

(pos. 4)

are protected by an immersed filter

(pos. 9)

,

placed inside the hydraulic fluid tank

(pos. 10)

whose

capacity is 120 litres.

The drive pump

(pos. 2)

is protected by another

cartridge-filter

(pos. 8)

, located on the suction line of

the boost pump, such pump being integral part of the

drive pump.

The one-way valve

(pos. 11)

set at 2.5 bar protects the

pump housing against high pressures and guarantees

a certain circulation of the drain oil to the hydrostatic

motor reducing, in this way, the temperature.

From port “G” of the drive pump

(pos. 2)

low-pressure

oil is taken (25-30 bar) and used for the anti-cavitation

circuit of the automatic levelling system of the forks and

for feeding the control circuit of the electro-proportional

distributor

(pos. 16)

which controls the movements of

the telescopic boom.

Summary of Contents for TELELIFT 3713 Elite

Page 4: ...Courtesy of Crane Market...