Document 57.4400.7200 - 1

st

Edition 03/2005

INDEX

v

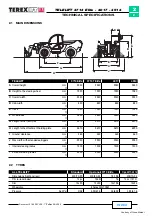

TELELIFT 3713 Elite - 4017 - 4514

INTRODUCTION

The control module of element 2 of the distributor is

the electro-proportional type with electrical feed-back

and integrated electronics. On the two control lines of

the cylinder

(pos. 19)

, and integral to module 2, there

are two pressure relief valves set at 295 bar which

protect the automatic levelling system of the forks when

the boom is moved up and down and in case of overload

on the attachment holding plate (ex. use of the bucket).

Module 3 of the distributor controls the boom telescopes

extension cylinder

(pos. 21)

. This cylinder is equipped

with a double-acting compensation valve with safety

function. The control module of this element of the

distributor is the electro-proportional type with electrical

feed-back and integrated electronics.

On the control line of the circular chamber of the cylinder

(pos. 21)

and integral to module 3, there is a pressure

relief valve set at 150 bar which limits the load when

the boom is extended in those working zones where

the electronic overturning control system cannot detect

overload conditions with respect to the load chart of

the machine.

Module 4 of the distributor controls the attachment

locking cylinder

(pos. 22)

. This cylinder has a double

one-way valve with hydraulic release and safety

function. The control module of this element of the

distributor is the ON/OFF electrical type with integrated

electronics.

On the feeding lines of this cylinder, there are two quick-

fit connectors

(pos. 23)

for the connection of the

hydraulic lines to the optional attachments which need

hydraulic power for their operation (ex. hydraulic winch

and maintenance jib, mixing bucket, etc.).

The SAFIM S6 servo-assisted braking system with pedal

(pos. 24)

receives oil from the pump

(pos. 4)

and uses

this oil to pressurise 3 hydraulic accumulators

connected to the same system. The oil at pressure

contained in these accumulator is then used to operate

the service brakes of the two axles

(pos. 25)

and

(pos.

26)

and to release the parking brake located inside the

front axle

(pos. 26)

.

The fill valve inside the braking system takes the flow

from the feeding line so the pressure on the line of the

accumulators reaches the calibration value of the cutout

valve set at 150 bar. When this pressure is reached, the

valve gradually releases all the flow to line B for other

uses.

The brake pedal located in the driving cab, which is an

integral part of the braking system S6, is connected to

two proportional sliders which control the two separated

lines of the service brake, one for each axle. In relation

to the stroke of these sliders, a gradual communication

between the feeding line, connected to two

accumulators which, at their turn, are connected to ports

R1 and R2 (the accumulators have 0.5-lt. capacity and

Summary of Contents for TELELIFT 3713 Elite

Page 4: ...Courtesy of Crane Market...