16

Usually thermocouples are combined with a module where they are connected electrically in series and

thermally in parallel between two ceramic plates.

Peltier phenomenon consists of the following. A contact potential difference always appears at the point of

junction of two different metals or semiconductors. If the electric current passes through them the potential

difference at the junction assists or counteracts the flow. So as the current passes against the field of the

potential difference the electrical source needs to expend additional energy to make the current pass through

the junction and this additional energy consumption results in heat energy output at the junction.

If the field of the potential difference has the same direction as the current the field supports it and enforces

the movement of the charges. This energy is drawn from the substance and as a result the temperature at the

junction is reduced.

So, one side of the thermoelectric module is cooled and the other is heated.

If the heat dissipation from the thermoelectric module’s hot side is provided efficiently, for example by a

heat sink, the temperature of the cold side could get down to tens of degrees below the ambient temperature.

In case the current changes its polarity the hot and cold sides would invert.

Any power plant produces waste heat, which can be used to generate additional power using a

thermoelectric generator (a form of energy recycling). This is potentially an enormous market.

In thermoelectric generators of the stove INDIGIRKA, when heated on one side and forced cooling of the

other between, the ceramic plates creates a sufficient temperature difference to generate electric current.

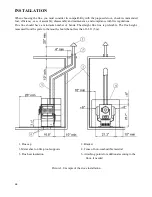

PACKAGING AND TRANSPORTATION

The stove is packed in packaging materials. A set of flue pipes is laid inside the stove without additional

packaging. If extra flue sections are required for proper operation they must be purchased separately.

Instruction for installation, operation and maintenance is in the packaging bag, embedded in the middle tube,

which is visible when you open the door.