fan, brings the woodlogs in the state of 'gasication' - the process where light weighted hydrocarbons. The

ame has a specyphic blue colour and the eciency of such solid fuel boiler is 10-15% greater than that of

the conventional ones. Another interesting property of wood gasication boilers is that the woodlogs are

placed in the upper chamber and the ame is inverse - going upside down contrary to conventional boilers.

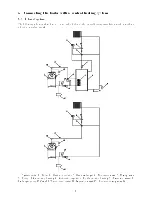

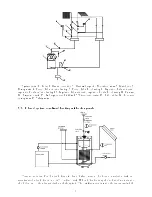

Wood gasication combustion requires a constant and stationary boiler operation. It is thus necessary

to have an additional heat tank to accept the excess heat made by boiler. It is also necessary to perfectly

adjust temperatures between the heat tank, ow and return line of the boiler to prevent condensation. All

in one, wood gasication allows maximum comfort with wood-logs as a fuel, but with certain investment

to be made into additional equipment.

The IGNIS boiler lls the room between the less pricey conventional boilers, which demand rell

of wood more often and maximum comfort yet more pricey wood gasication boilers (with heat tank).

Because of its technical construction IGNIS allows the wood gasication eect (in amoutn much less

than 'real' wood gasication boilers) but only using the natural draught of the boiler, without a fan and

without a necessary heat tank. What is still necessary is the protection against condensation (mixed

valve, by pass of the boiler). IGNIS does not have an inverse ame.

As it does not posses the automatic regulation via fan, optimum combustion is achieved by setting the

primary and secondary air. Primary air is controlled by the draught regulator (to be ordered separately)

and the secondary air is to be set manually.

In which way the wood gasication eect is achieved? Wood gasication process takes place in the

upper zone of the boiler - within the so-called 'reproof catalyst'. This is a special cylindric part of the

heating chamber. On its upper side there are special heat exchangers (tubulators). Below the catalyst

with presence of secondary air, at very high temperatures, solid particles are accelerated to certain level

until they combust completely. Short-chain hydrocarbons are released. Flue gases are passing through

turbulators - in contact with increased surface of the tubulators ue gases are additionally cooled down -

exit ue gas temperature is thus lower compared with conventional boilers. The eciency is higher. The

concentration of dust, particles and COX/NOX is lower.

IGNIS has a secondary ap inside the chamber. The role of this is to shorten the passage of ue

gases and increase the draught in the boiler when necessary (during ignition for instance). when th ere

is stable this secondary ap should be closed. IGNIS also has a so-called 'ue-box'. Water content of the

boiler is maximized occupying a part of the ue chamber.

3 Recommendations for boiler shipment and storage

3.1 Delivery form

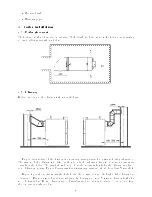

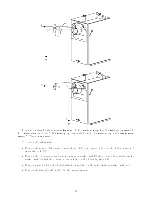

The boiler comes in three parts, boiler chamber, pellet storage and the boiler housing packed separately.

Chamber is wrapped with plastic sheet, and upper door containing reproof glass should have a small

styrofoam protection sheet. The whole set is transported on wood pallet.

The boiler must always stand in its vertical position. The rotation of the boiler during the shipment or

installation represents a serious risk and can lead to damaging the boiler. It is forbidden to stack boilers

vertically one onto other.

The boiler can be stored only in closed rooms with no atmospheric inuence. The humidity in the storing

room also must not exceed the critical value of 80%, so as not to create any condensate. The temperature

of the storing room must be in the range of +/- 40 C.

3.2 What's in the box

The following parts are supplied together with the boiler:

•

Cleaning kit

4

Summary of Contents for IGNIS

Page 7: ...6 ...