It is not necessary to install the heat accumulator. However, it is recommended.For 1 KW power of

the boiler, a capacity of the heat accumulator of 25-50 l is recommended. One must also bear in mind

that the power of the boiler must be enough in order to both warm up the water in the accumulator,

as well as to provide direct feed to the installation in very cold periods the chosen power of the boiler

should be 1.5 higher than the power of an oil-gas boiler for the given squaring.

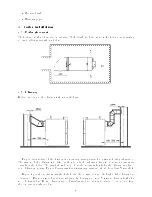

It is recommended that the closed central heating system is supplied with an expansion tank, the

capacity of which must amount to at least one tenth of the total capacity of the system (including the

water volume in the boiler). The system must also have an automatic aeration valve with the help of

which air will be eliminated from the system. The use of a safety valve is obligatory (with a 2-3 bar

threshold, depending on the power of the boiler) and it must be mounted near the boiler.

It is also necessary that the system has a thermometer and manometer in order to read the temperature

and pressure in the system. In case of using conventional solid fuel, the temperature of the return line

should not fall below 60C, so as to avoid leaking, i.e. condensation in the boiler, which can further lead

to corrosion. The temperature of the starting line should not fall below 70C. It is recommended to use

a four-arm mixing valve on the return line of the boiler or a regulation group such as LADDOMAT 21.

It is also recommended to mount a lth catcher on the return line.

Qualied installer should be entrusted with the mounting of the heating and the initial operation.

This must be a person who will take over the responsibility and guarantee the correct operation of the

boiler and of the complete central heating system. In the case of an incorrectly planned system with

manifesting deciencies caused by the respective person's incorrect installation of the system, which can

again lead to an incorrect operation of the boiler, the complete liability for the material damage and

potential new costs arising in relation to it is borne exclusively by the person who was entrusted with

the mounting of the central heating system, and not by the boiler manufacturer, sales representative or

seller.

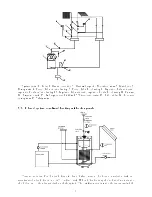

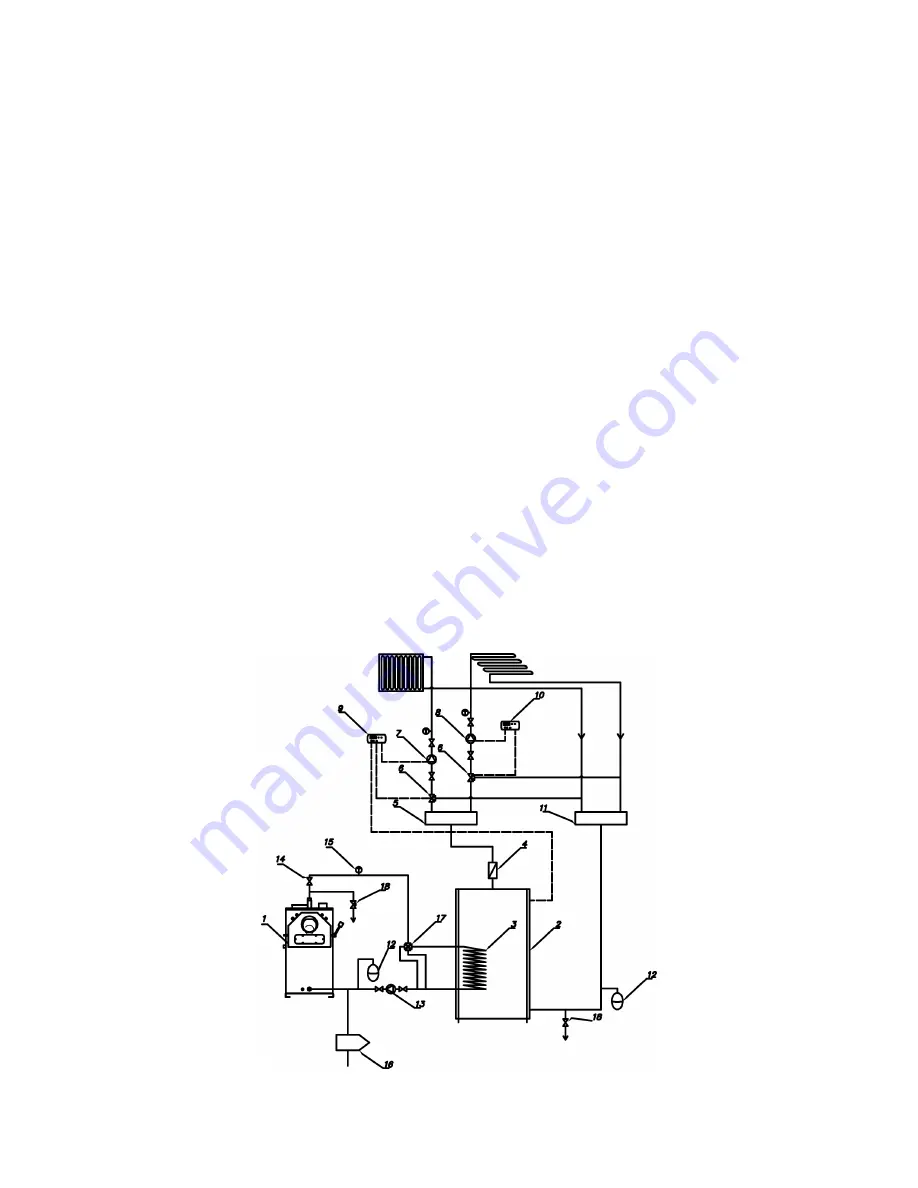

5.2 Closed system combined heating with solar panels

The following scheme depicts a heating system connected over a hybrid solar boiler within an accumalation

tank:

8

Summary of Contents for IGNIS

Page 7: ...6 ...