We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5

2

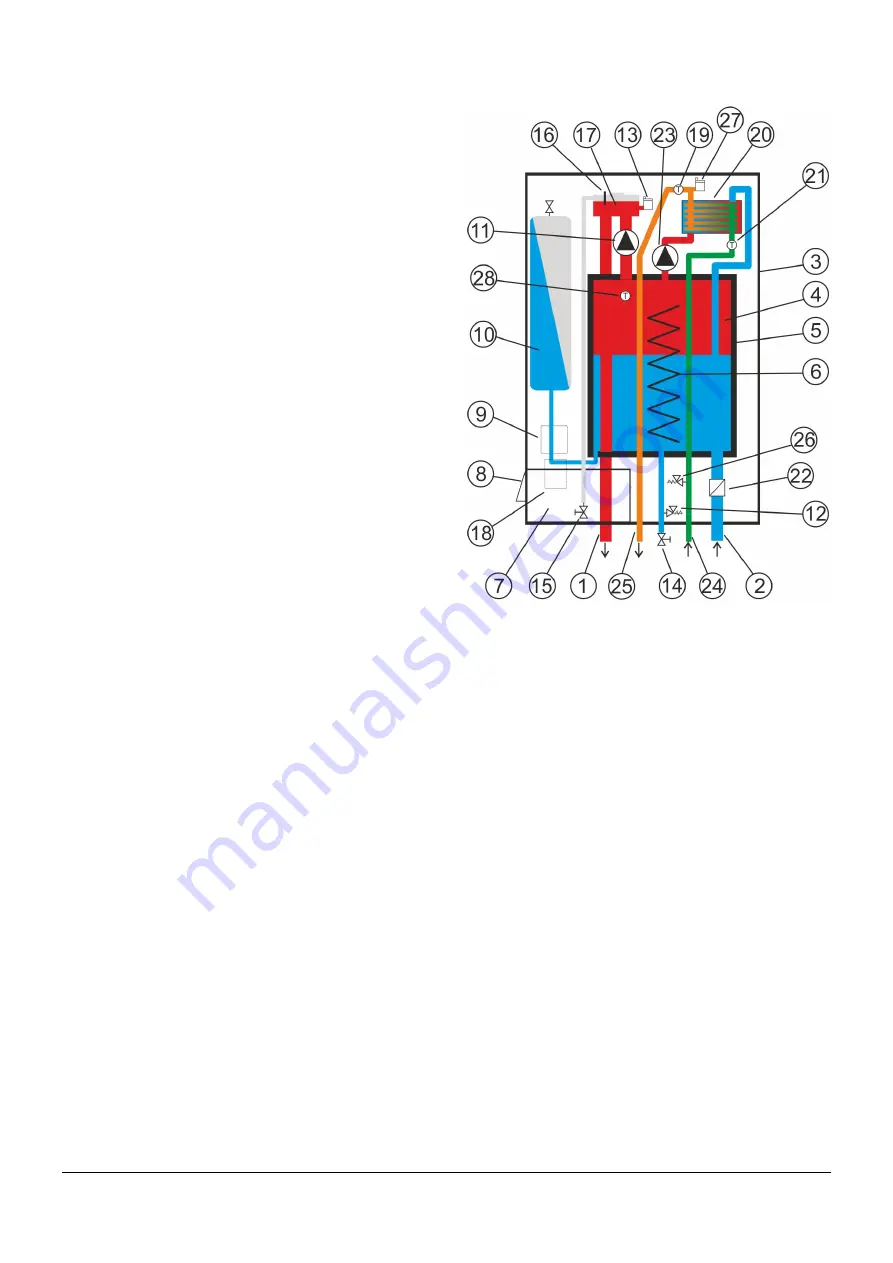

2.2. Integral parts of the TERMO-Kombi

Boiler

1. Central heating primary flow

2. Central heating return flow

3.

External shell of the boiler

4. Boiler

5. Thermal insulation

6.

Electric heaters

7. Control panel

8.

Boots for el. terminals

9. Contactors

10.

Expansion vessel

11. Central heating pump

12. Safety valve at 3 bar

13. Automatic venting valve

14.

Filling and emptying valve (in packing, it should

be built in at installation)

15. Valve for boiler venting

16.

Sounding tube for air appearance control

17. Distributor

18.

Miniature circuit breaker (MCB)

19. Temperature sensor of sanitary water outlet line

20.

Exchanger

21. Temperature sensor of sanitary water inlet line

22. Non-return valve

23. Pump for sanitary water preparation

24. Sanitary water intake

25. Sanitary water output

26.

Safety valve at 8 bar

27. Automatic venting valve

28.

Boiler’s temperature sensor