26

EOS-EWS_42-53_U161600

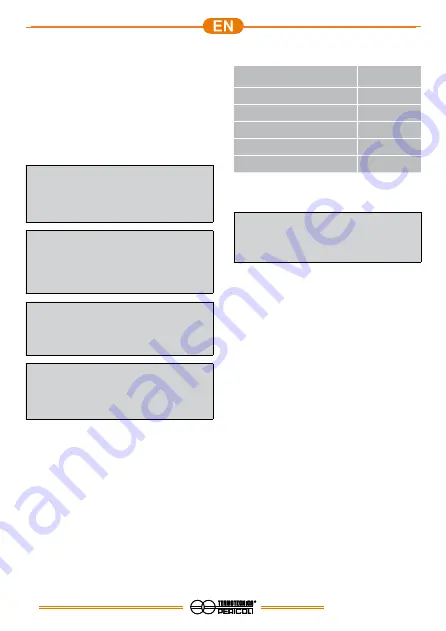

The following table specifies the periodic routine checks that the

user must perform to maintain the machine in good condition.

INTERVENTION

FREQUENCY

LUBRICATION OF THE MACHINE

never

CLEANING OF THE MACHINE

weekly

ADJUSTMENT OF THE DRIVE BELT

TENSION

quarterly

SCREW TIGHTNESS CHECK

quarterly

REPLACEMENT OF THE DRIVE BELT

when necessary

7.2 MACHINE CLEANING

WARNING

Never perform cleaning operations with the extractor running.

Also for external cleaning of the machine, the safety nets and

the shutter blades, prior disconnection from the mains supply

required.

Observe the following provisions, to be performed regularly to

ensure proper cleaning and proper operation of the product.

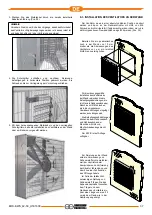

•

Clean the motor casing regularly with a brush or compressed air

(do not spray water or steam).

Regular cleaning of the motor is particularly important when the

extractor operates in dusty or dirty environments, because the

motor must be able to dissipate the heat generated.

On the motor models where they are present, use the plastic

caps placed on the cover and on the drawer of the motor to

discharge any condensate accumulated inside the motor itself;

at the end of the operation, restore the initial conditions.

•

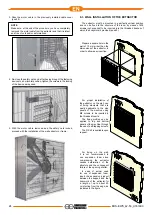

On the bottom of the bearing structure of the extractor, there are

2 holes to discharge any water formed; keep the bottom clean

and free holes to avoid corrosion.

•

Keep the shutter blades and safety nets clean to prevent

excessive resistance during operation.

•

Keeps the levers (pos.30) of the shutter blades below the

shoulder cover clean.

On the EOS model, pay considerable attention to the cleaning

of the movement device of the blade. On the EWS model

thoroughly clean the blade opening centrifugal mechanism.

•

The propeller blades do not require special maintenance

because they are self cleaning.

•

When using a high pressure cleaner for cleaning, do not direct

the jet of water or steam directly on the motor or central pulley

or above the opening mechanisms.

7.3 MACHINE LUBRICATION

The ball bearing inserted into the driven pulley (pos. 17) is

permanently lubricated and requires no special care; the same

applies to the motor bearings.

The plastic parts (levers) that move the shutter flaps must not be

completely lubricated or greased to prevent accumulations of dust

and harmful deposits.

7.1 MAINTENANCE REQUIREMENTS

Air extractors made by TERMOTECNICA PERICOLI S.R.L.

are designed and manufactured for long life even under the most

severe service conditions.

Please remember however that this equipment HAS moving

parts, and as such they need to be checked regularly.

It is therefore recommended to implement a preventive

maintenance program, which will be entrusted to skilled and

competent personnel.

The daily inspection must be performed to prevent any failure

due to adverse effects of the working environment such as

temperature, humidity, dust, dirt and vibration, and other factors.

WARNING

The maintenance of the extractor must be performed only by

trained personnel in compliance with safety standards and

requirements set forth in this Manual.

Before connecting to the mains, isolate the power line by

opening the main switch.

WARNING

In the machine maintenance and inspection phases there is a

risk of entanglement and cutting of clothes, limbs, hair or other

parts of the body by the fan.

During these phases acquire the PPE, in particular safety

clothing and gloves, tie long hair back and do not wear rings,

bracelets or necklaces.

CAUTION

To ensure a high level of safety, use only original spare parts

available from your supplier. In case of using non-original parts,

full functionality and compliance with EC directives regarding

electrical safety and electromagnetic compatibility are not

ensured.

WARNING

When working on the machine, it is necessary to make all

personnel are aware of this.

In the event of maintenance work, affix a warning sign onto

the power supply switch to inhibit accidental operation by a

second operator.

Regularly carry out the following operations:

•

Ensure that the inlet and outlet openings are clean and free

of objects.

•

Ensure the extractor is always dry. If the extractor appears wet,

dry it immediately; identify the cause and remedy to prevent

corrosion.

•

Check the cable connections and connectors. In the event of

loose connections, damaged cables, or other abnormalities,

stop the extractor immediately and seek specialised assistance

or technicians.

•

Check for bolts or nuts that are loose or rusted because of

environmental conditions. In this case, tighten or replace.

•

Check for any deposits inside the equipment. In the case,

remove the deposits by compressed air jets.

Summary of Contents for EOS 42/0,5

Page 63: ......