27

EOS-EWS_42-53_U161600

M8 Nuts and motor plate

(pos. 13)

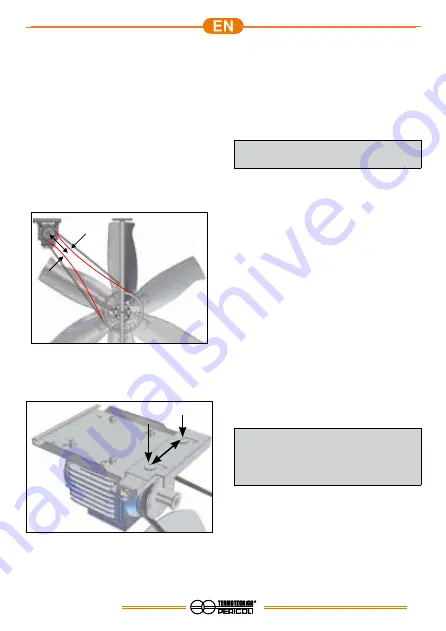

7.4 ADJUSTMENT OF THE BELT TENSION DRIVE

The extractor, in the preassembled versions, comes with correct

tensioning of the drive belt (pos.21).

In the versions to be assembled, the following procedure must be

followed for correct belt tensioning during installation.

To ensure greater duration of the extractor, it is advisable to

check the tensioning of the belt at the end of installation and each

time a maintenance cycle is performed.

1. On the air inlet side, loosen the screws that secure the net

fastening devices (pos.31), rotate them and open the two nets

(pos.19).

2. Remove the protective casing (pos.27) of the drive belt, if

present.

3. Press the branches of the belt in the intermediate zone, about

30 cm from the motor pulley, and if there is a distance between

the branches of the belt of about 12/13 cm, it means that the

tension is correct. If there is a greater distance, it means that

the tension is below the design value.

In this case the the adjustment of slippage system allows the

correct value to be restored.

4. Loosen the 2 M8 nuts that secure the motor plate (pos.13).

5. Slide the motor plate in the opposite direction to the propeller

until reaching the position with optimum belt tension.

6. Retighten the 2 M8 nuts to the torque required by section 7.5

“Screw tightness check”.

7.

Refit the casing (pos.27), if present, close the nets again and

finally tighten the screws on the net fixing devices.

7.5 SCREW TIGHTNESS CHECK

Regularly check the tightness of the bolts and nuts in the

following points:

• M8 motor mounting screws, specified torque:

- 18 Nm

•

screw between the pulley and motor, torque required:

- 10 Nm (M6 screws) using threadlocker (medium strength)

- 25 Nm (M8 screws) using threadlocker (medium strength)

CAUTION

Incorrect values in the torque can cause damage to the

equipment!

7.6 REPLACEMENT OF THE DRIVE BELT

When the belt is frayed, with obvious signs of wear, or in the case

of tears, it is necessary to replace it.

1. On the air inlet side, loosen the screws that secure the net fastening

devices (pos.31), rotate them and open the two nets (pos.19).

2. Remove the protective casing (pos.27) of the drive belt, if present.

3. To remove the worn belt, push the branches of the belt in the

intermediate area to the pulleys towards the inside of the fan

(toward the air outlet side) and simultaneously rotate the propeller.

Once freed from the pulleys, remove the belt between a

propeller blade and the orifice by repeating this process for the

other five blades.

4.

Insert a new drive belt between a propeller blade and the orifice,

working accordingly for the other five blades.

5. Fit the belt on the motor pulley and as far as possible on the

driven pulley, then rotate the propeller with force to lift the entire

belt into the groove of the driven pulley.

6.

Check the deflection of the V-belt, if the tension is too low

please adjust. The motor plate position to obtain the deflection

indicated in the preceding paragraph.

7.

Refit the casing (pos.27), if present, close the nets again and

finally tighten the screws on the net fixing devices.

7.7 TROUBLESHOOTING

WARNING

The repairing of the extractor must be performed only by

trained personnel in compliance with safety standards and

requirements set forth in this Manual.

Before any type of repair, isolate the power line by opening

the main switch.

Problems of non-operation may be due to the following causes:

•

the main switch is off;

•

incorrect adjustment or failure of the automatic control;

•

defective fuses;

•

dirt in the propeller and/or the inner ring of the conveyor;

•

open circuit in the connection box or outlet.

If assistance or service is necessary by TERMOTECNICA

PERICOLI S.R.L. technical personnel, contact your local sales

representative or Distributor.

30

cm

12/13 cm

Summary of Contents for EOS 42/0,5

Page 63: ......