Terradonis is a registered trademark of ICS

ZA de Croix Fort - 12 rue du Soleil - 17220 La Jarrie

- France -

Tel: +33 5 4635 2828, Fax: +33 5 4635 2829

contact@ics-agri.com

www.terradonis.com

➜

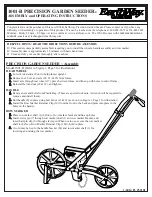

BRUSH:

The brush controls seed output through the disc’s holes,

ensuring that a predefined number of seeds is released through each hole.

Loosen the 2 wing screws to adjust the brush. The higher the brush,

the greater the number of seeds released. Hence, when the brush is lowered,

fewer seeds are released.

The standard brush position is when it skims against the sowing disc.

➜

GUIDe plate:

The guide plate consists of 2 forks.

These forks guide theseeds to the sowing holes,

as shown opposite:

➜

SeeDING DIStaNCeS:

The distances between the seeding can be adjusted by

adjusting the pinions and the number of holes in the disc, see the seed distance table.

note:

the actual planting distances may vary depending on soil quality and speed

of work. Test intervals based on the ground before you start planting.

➜

plaNtING DeptH:

Planting depth may be adjusted by lowering or raising

the shoe.

➜

SoIl CoveR:

Adjust the angle of the filler blade for optimal soil cover.

➜

HeIGHt of tHe HaNDle:

The handle height can be adjusted by loosening

the screws at the base of the fork of the handle and the buttons

on each of its removable parts and by adjusting them according to your needs.

➜

CleaNING:

If soil sticks to the compaction wheel, the contact surface must be

cleaned before it sticks (it might deposit oil or dirt).

seTTinGs

➜

Lubricate all revolving parts, except for the sowing disc.

➜

The brush, the guide plate, the spongy rubber of the transmission wheel and

the spongy rubber of the compaction wheel are consumables.

Check them regularly and replace as necessary.

➜

Make sure the seedbed is uniform.

➜

Check the sowing disc for fouling with dirt, pesticides, or seed coating

residues. Clean the disc if necessary.

➜

Prepare a seedbed by carefully hoeing and levelling.

➜

Excessive speed can damage the precision of the work.

Optimal speed : 2 km/h

➜

Seeds must not be wet. Do not wet coated seeds.

insTrucTions For use

4

5

Disc Thickness

Number of

holes

Diameter

Placement

A1

5

8

8

A2

6

10.5

A3

12

C1

13.5

C2

5

17

A11

6

16

8

A22

10.5

A33

12

B1

5

16 on 2 lines

8

B2

6

10.5

Disc Thickness

Number of

holes

Diamètre

Diameter

E1

4

72

9

E2

10

S2

6

16

6.8

W1

8.6

W2

10.6

X

6

-

-

F8-66

6

8

10.5

F8-86

8

12

F8-88

8

seedinG discs sPeciFicaTions

seTTinGs