5

INSTALLATION

INSTALLING BALLAST

CAUTION:

Avoid Injury!

Machine can become unstable

when operating with attachment. Ballast is required when the

attachment is installed.

When the attachments is removed, also remove any ballast

that was added to the machine.

Use only attachments and accessories recommended by the

manufacturer.

Refer to your tractors operator’s manual to determine the required front

ballast weight. When filled with liquid, the 45-gallon sprayer weights

620 lbs (281 Kg).

ATTACHING SPRAYER TO TRACTOR

1. Park machine safely and on level ground.

2. Lower tractor lift link to lowest position.

3. Mount sprayer on 3-point hitch and install lynch pins.

4. Attach sprayer harness to switch harness making sure harness is

clear of any pinch points.

5. Level sprayer by adjusting the top link and draft link on the

3-point hitch.

ATTACHING SPRAYER TO TRACTOR WITH QUICK HITCH

1. Install bushing set (sold separately), Terra-King part number

TK95029, on to sprayer.

2. With sprayer on level ground, lower 3-point hitch aligning the center

hook just below the top pin on the sprayer.

3. Back tractor into position and ensure all three connection points are

aligned.

4. Raise 3-point hitch and ensure all three pins are fully engaged with

the quick hitch.

5.

Lock lower connections on quick hitch following the manufacture's

directions.

6. Level sprayer by adjusting the top link and draft link on the

3-point hitch.

7. Attach sprayer harness to switch harness making sure harness is

clear of any pinch points.

REMOVAL AND STORAGE

REMOVING SPRAYER FROM TRACTOR

1. Park machine safely and on level ground.

2. Empty the sprayer tank.

3. Lower the sprayer to the ground.

4. Disconnect the sprayer harness from the switch harness and store

on top of sprayer.

5. Disconnect sprayer from 3-point hitch, refer to quick hitch

manufacture's instructions if using quick hitch.

6. Remove any added ballast from tractor.

OPERATION

CAUTION:

Connect to a 12 V battery only.

PSI PRESSURE GAUGE

Wrap threads of pressure gauge with sealant tape before attaching to

the sprayer.

CAUTION:

Do not overtighten. Only hand tighten the pressure

gauge to the sprayer valve.

CALIBRATING THE SPRAYER

When spraying with boom, sprayer must be calibrated to ensure proper

spray coverage and to combat over-application or under-application.

The calibration process consists of three steps:

1. Calculate speed of tractor.

2. Determine nozzle size and consult calibration chart for desired or

instructed gallon per acre (GPA).

3. Set pressure using relief valve.

CALCULATING THE SPEED

It is important to determine what speed the tractor will be traveling

while spraying. Even if tractor has a speedometer, it is still

recommended that speed be checked for accuracy. Perform the

following steps to determine speed:

1.

Measure a 200 or 300 foot distance on a field or surface similar to

where sprayer will be used.

2. Drive tractor with half-full sprayer across measured distance at

a constant and comfortable speed for spraying. There can be no

changes in speed while measuring time.

3. Determine amount of time, in seconds, it takes to travel the

measured distance.

4. Speed can be determined with the following equation:

speed (mph) = (distance (ft) x 60) / (time (sec) x 88) or by

consulting the following table.

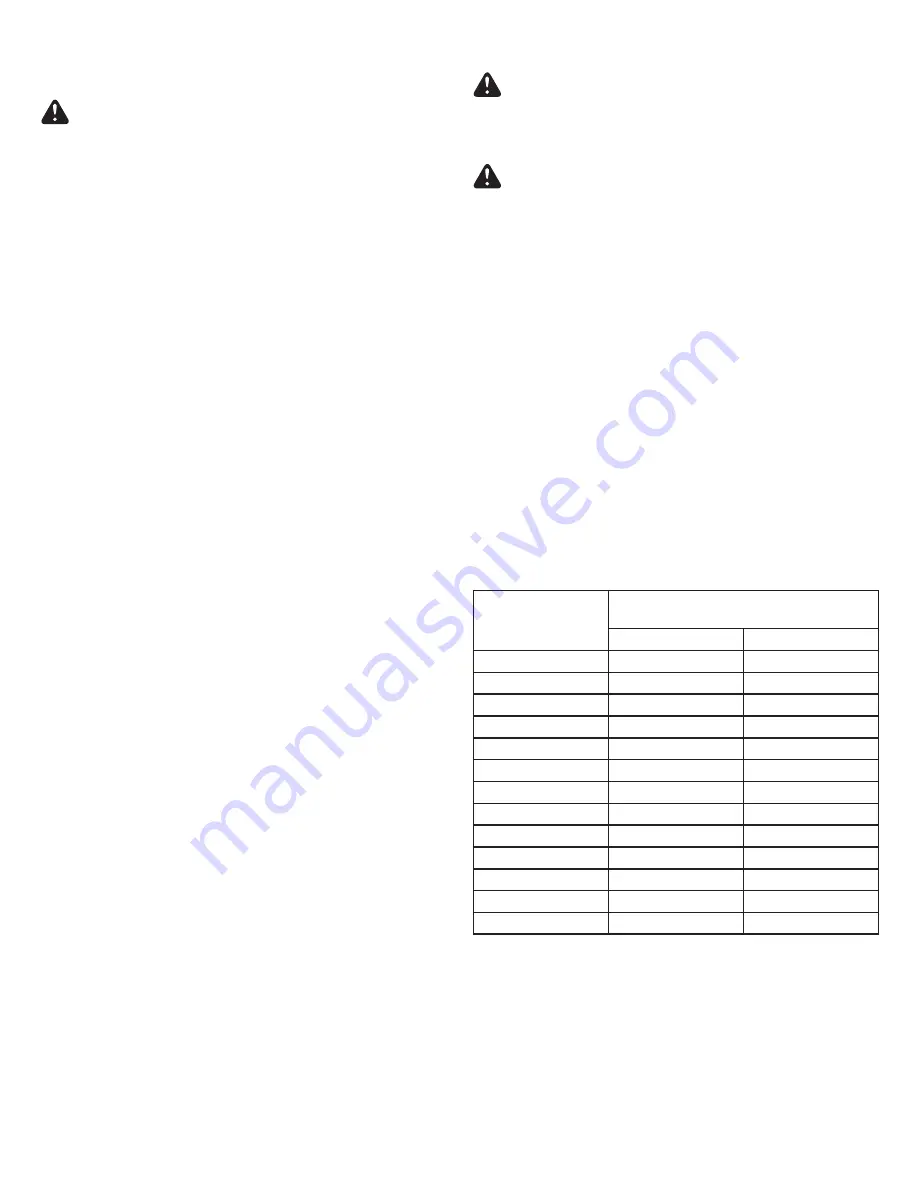

Speed in MPH

Time (sec) required to travel

a distance of:

200 ft

300 ft

1.0

136

205

1.5

91

136

2.0

68

102

2.5

55

82

3.0

45

68

3.5

39

56

4.0

34

51

4.5

30

45

5.0

27

41

5.5

25

37

6.0

23

34

6.5

21

31

7.0

19

29

USEFUL FORMULAS

GPA = Gallons per Acre

GPM = Gallons per Minute

MPH = Miles per Hour

GAL/1000 sq ft = Gallons per 1000 sq ft

W = Nozzle spacing in inches

GPM Per Nozzle = GPA x MPH x W / 5940

GPM Per Nozzle = GAL/1000 sq ft x MPH x W / 136

GPA = 5940 x GPM (Per Nozzle) / MPH x W

GPA = Gallons per 1000 sq ft / 0.023

GAL/1000 sq ft = 136 x GPM (Per Nozzle) / MPH x W