OPERATIVE MANUAL

MN-L20-A1

DC-18-10

MEC-RELA®

- www.mecrela.it – mecrela@terranova-instruments.com

a TERRANOVA® Srl brand

- www.terranova-instruments.com - VAT IT07848810151

Factory & Sales: Via Gramsci 1 – 26827 Terranova dei Passerini (LO) – Italy

Head Office: Via Rosso Medardo 16 – 20159 Milano – Italy Ph: +39 0377 919119 – Fax: +39 0377

855720

Pa

g.

8

/24

4

INSTALLATION

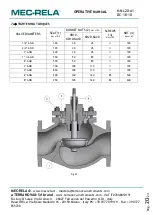

The valve body casting is marked with an arrow showing the direction of flow and its

normal flow path. The casting also has markings which show the type of material and

maximum operating pressure. Before installing the valve, make sure that the inside of the

is clean, by performing, if required, an energetic blowing with steam or compressed air.

This should be done with caution.

The installation of a filter (pos. A Fig. 1) upstream the valve will prevent dirt entering the

valve.

To allow periodical maintenance of valves that are installed on continuously operating

systems, it is recommended to install two Isolating valves, located upstream (pos. B Fig. 1)

and downstream (pos. C Fig. 1) of the control valve, and a by-pass one (pos. D Fig. 1). Use

the by-pass valve (pos. D Fig. 1) to manually regulate the process when the control valve is

temporarily disconnected.

The two shut-off valves must have the same internal diameter of the control valve. During

the installation of the valve, make sure that the flow in the pipe goes in the same direction

as indicated by the arrow on the valve body.

Fig. 1 - Installation diagram

The assembling position of the valve does not limit its operation, but it is recommended to

assemble the valve with the actuator pointed upward (pos. E Fig. 1) as other positions may

allow the accumulation of any impurities which are contained in the fluid thus damaging

the valve itself.