MAINTENANCE

2-5

Page 8

TESCO EQUIPMENT LLC

ML50-30 MAINTENANCE LIFT

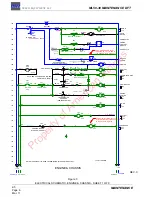

Figure 5

ELECTRICAL SCHEMATIC, LIFT & STAB. CONTROL - SHEET 3 OF 9

LIFT & STABILIZERS CONTROL

BODY DOWN

STABILIZER

EXTENDED

LOWER E-STOP

PENDANT E-STOP

(CLOSED WHEN EXT'D)

STABL. EXT'D

BODY UP

ENGINE STOP

R

BODY DOWN

LIFT MODE

LT6

STAB EXT'D

A

261

150

217

152

259

LIFT MODE

G

IP

IP

IP

LIFT POWER

[OPT.]

BODY UP

STABS

NOT STOWED

200 -

201 -

202 -

203 -

204 -

205 -

206 -

207 -

208 -

209 -

212 -

210 -

211 -

213 -

214 -

215 -

216 -

217 -

218 -

219 -

220 -

221 -

222 -

223 -

224 -

225 -

226 -

227 -

IGN

+12V

+12V

UC

GC

SW9

SW10-B

221

- 12V

- 12V

GC5

GC6

PC7

PC8

LT7

LT8

SW10-A

UC

UPPER E-STOP

UC7

UCS8

UCS7

PC8

UC8

219

125

STABILIZER

STOWED

STABL. STOWED

PS5

ST

1

3

2

(CLOSED WHEN STOWED)

SC

PS7

(BODY DOWN)

1

3

2

ST

PS2

ST

PS2

200

ST

STABILIZER

STOWED

PS2

B ENGINE STOP

[OPT.]

OVERRIDE [OPT]

STABL. EXT'D

STABL. EXT'D

STABL. EXT'D

[OPT. MULTIPLE STABILIZER SWITCHES]

STABL. STOWED

LS6-A

LS6-B

LS6-C

113

IP

ST

ST

ST

SW11

E

CC1-D

[OPT.]

105

OPT. +12V LIFT SIGNAL

FOR HIGH THROTTLE

FOR CHASSIS OTHER

THAN FORD

STABL. STOWED

PS5-A

ST

1

3

2

PS5-B

PS5-C

ST

ST

1

3

2

1

3

2

PS5-B

PS5-C

ST

ST

1

3

2

1

3

2

30

CR4

87A

30

R13

87

8

6

CR4

CR6

(BRAKE SET)

85

86

CR7

R15

R16

R16

4

1

(NEUTRAL)

(NEUTRAL)

STABL. EXT'D

(BODY DOWN)

CB3

20A

LIFT CONTROL

LIFT MODE

86

85

R14

(STABS STOWED)

118

120

118

213

207

MB

MB

MB

MB

(LIFT MODE)

30

87

CR6

203

MB

MB

MB

MB

D2

D3

D4

R12 114

(ENGINE RUNNING)

IGN

LIFT

MODE

7

2

7

2

1

4

8

6

IGN

IGN

IGN

IGN

17

18

J16

18

17A

17

37

21

37

22

22

23

24

LIFT

25

26

27

27

27

BODY DOWN

BODY DOWN

IGN

IGN

+12V

MAIN BOX

LIFT

21

23

24

25

26

27

19

J8

J15

J9

R14

STABL. STOWED

MB

7

2

20

20

IGN

86

STABL. STOWED

85

CR13

[ENG. STOP OPT.]

MB

30

CR13

87A

(STAB STOWED)

205

36

17B

17B

17C

30

CR14

87A

(STAB STOWED)

109

7

CHASSIS

Black

Red

Orange/Blk

Orange/Red

Blue/Blk

Blue/Red

Black

Black/Red

Brown (4)

Blue (4)

Brown

Rh/Wht

Gr/Ylw

Rd/Blk

Black

Black

0.2A

0.2A

0.4A

0.4A

1.5A

1.5A

1.5A

13.2A

13.2A

4.5A

1.5A

1.5A

0.4A

0.2A

Mar. 17

Property of American Airlines