4 Transmitter

19

4.3.1.1.

Without stainless steel measurement chamber and cooling

coil

CAUTION

Compressed air! Danger of injury!

> De-pressurize pipe sections (e.g. compressor off or use of

bypass) and vent them before opening.

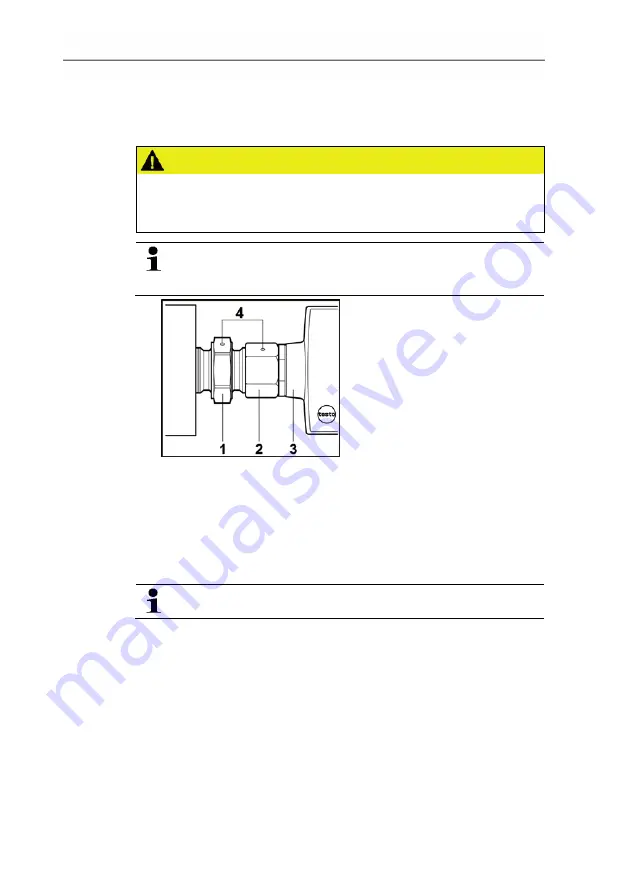

Clamp ring screw connection is already pre-assembled.

Screw connection body (1) and union nut (2) have a point-

shaped marking (4).

1.

Screw thread in process.

2.

Turn housing (3) to desired position without much exertion

of energy.

3.

Tighten union nut (2) finger-tight.

4.

Hold screw connection body (1) with a suitable spanner.

5.

Tighten union nut (2) slightly past the marking (4).

An increased resistance can be felt when tightening.

6.

Close ventilation of the pipe section and pressurize the pipe

section again.

4.3.1.2.

With stainless steel measurement chamber (max. 35,000 hPa)

1.

Screw process connection (G1/2) of the testo 6781 transmitter

into the thread of the measurement chamber.

2. Mount 6781 as described under Without stainless steel

measurement chamber and cooling coil page 19.

3.

Engage quick-release fastening of the measurement chamber

in the standardized socket of the compressed air line.