10

Instructions for use and maintenance

EN

2.2.

Temperature setup (for models with adjustable

thermostat)

This setup allows the gradual setting of the desired

temperature, achieved by using a handle on the control panel.

Turn the knob to the upward indication, in order to increase

the temperature of the hot water.

Place the thermostat knob in position for maximum

temperature (unless it is on this position constantly), for

period of one day each month - see

Table-I (h)

Thermostat temperature

setting. This ensures higher hygiene of the used hot water.

I

MPORTANT

: Models that do not have thermostat

control knobs have automatic water temperature

preset by the manufacturer .

Position

e

(Energy-save mode) – At this mode, water

temperature reaches up to approximately 60°С. Heat losses are

reduced in this way.

3.

Аnti-freezing“ function

Place the thermostat knob in position „Аnti-freezing“

according to fig.2. With this setup the device maintains

temperature that does not allow the water freeze in it.

The electrical supply of the appliance should be

turned on and so must be the appliance. The safety

valve and the pipe between the valve and the appliance must

be protected from freezing. In case that for some reason the

electrical supply is cut off, there is a risk of freezing of the

water in the water tank. For this reason we recommend

draining the water out of the appliance before long absences

(longer than a week).

4.

Protection according to the temperature (valid for all models).

The appliance is equipped with a special facility (thermal

circuit-breaker) for protection against over-heating of the

water, which is switching off the heater from the electricity

network, when the temperature reaches too high values.

When this device operates, it does not self-reset and the

appliance will not work. Please call an authorized service

for solving the problem.

VII.

MODELS EQUIPPED WITH A HEAT EXCHANGER

(SERPENTINE TUBE).

These are appliances with inbuilt heat exchanger and are

intended to be connected to the heating system with

maximum temperature of the heat carrier of 80°C.

The control over the flow through the heat exchanger is a

matter of solution for the particular installation, whereby the

choice should be made at its design (e.g. external thermostat

that measures the temperature in the water tank and operates

a circulation pump or a magnet valve).

Water heaters with a heat exchanger provide the opportunity

for the water to be heated in two ways:

1.

by means of a heat exchanger (coil) – a primary way of heating

the water,

2.

by means of an auxiliary electrical heating element with

automatic operation, built in the appliance – it is used only

when additional heating of the water is needed or in case of

repairs to the system of the heat exchanger (coil). The proper

way of connecting the appliance to the electric network

and how to work with it has been specified in the previous

paragraphs.

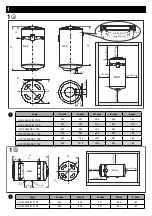

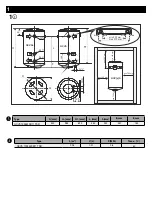

Mounting:

In addition to the mounting manner outlined above, especially

for the latter models, it shall be required to connect the heat

exchanger to the heating installation. The connections are to

be carried out in observance of the direction indicated by the

arrows on Fig. 1c.

Technical parameters (

table 4

:

Surface of serpentine [m²] - S;

Volume of serpentine [l] - V;

Operational pressure of serpentine [MPa] - P;

Maximum temperature of heat carrier [°C] - Tmax.

We recommend you mount stopcocks at the heat exchanger’s

entry and exit points. By stopping the flow of the thermophore

via the lower (stopcock) you shall avoid the unnecessary

circulation of the thermophore during periods of use only of the

electric heating element.

Upon disassembly of you water heater equipped with a heat

exchanger you must close both stopcocks.

There is a connexion with internal thread of ½” welded to

the water tank for the purposes of installing thermal probe –

marked with „TS”. The appliance is fitted with brass pocket for

a thermal probe which should be screwed into the aforesaid

connexion.

The usage of dielectric bushings for connecting the heat

exchanger to an installation of copper pipes is obligatory.

For ensuring minimal corrosion, pipes with a limited

diffusion of gasses must be used in the installation.

VIII.

PERIODIC MAINTENANCE

Under normal use of the heater, under the influence of high

temperature, lime scale /the so-called lime scale layer/ is

deposited upon the heating element’s surface. This worsens

the heat exchange between the heating element and water.

The heating element’s surface temperature increases along /

of boiling water/. The thermoregulator begins to switch on

and off more frequently. A ‘’deceptive” activation of the thermal

protection is possible. Due to these facts, the manufacturer

recommends preventive maintenance of your water heater

every two years by an authorized service center or service

base. This protective maintenance must include cleaning and

inspection of the anode protector (for water heaters with

glass-ceramic coating), which shall be replace with a new one

if need arises.

In order to clean the appliances use a damp cloth. Do not clean

with abrasive or solvent content detergents. Do not pour

water over the appliance.

The manufacturer does not bare the responsibility for all

consequences caused by not obeying the instructions, given

hereby.

Instructions for protecting the environment

Old electric appliances contain precious materials

and thus should not be thrown together with the

household litter. We kindly ask you make your active

contribution for protecting the resources and the

environment by handing over the appliance in the

authorized buy-back stations (if such exist).

Summary of Contents for GCH 503520 B12 TSR

Page 2: ......

Page 22: ...4 H O 2 H O 2 A 3...

Page 23: ......

Page 24: ...205881_003 TESY Ltd Shumen 9700 48 Blvd Madara PHONE 359 54 859 129 office tesy com...