Useful information

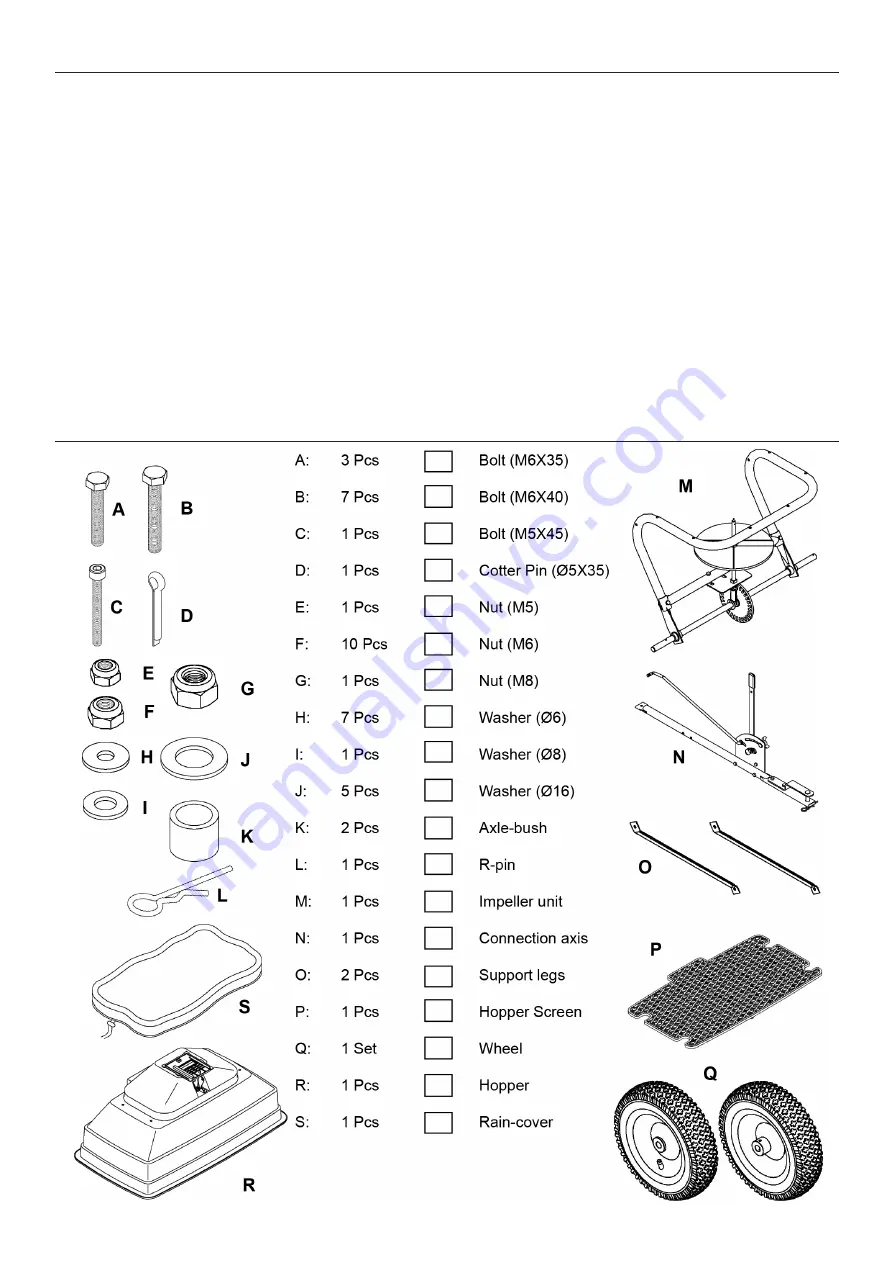

Identification of parts

General:

The distribution of wet or moist material will change the dispersion pattern and increase the risk of clogging

the impeller. Clean your spreader thoroughly after each use. Be especially thorough around the impeller

and other rotating parts.

Assembly:

To ensure a smooth dispersion it is essential that the gear and impeller is fitted properly. Ensure that the

plates on the impeller unit are aligned with the gear and connection axis. If the gear and connection axis

are not aligned, the impeller wheel will run slow and uneven.

Maintenance:

After each use; always clean the impeller parts of the spreader. This will reduce the risk of clogging the

impeller wheel and mouthing. Dirt in the impeller wheel, will give an uneven dispersion.

Operation:

The machine is designed to be operated at normal walking speed. Slower or faster speeds, will change the

dispersion patterns.

6