CONTROLS AND INSTRUMENTS

13

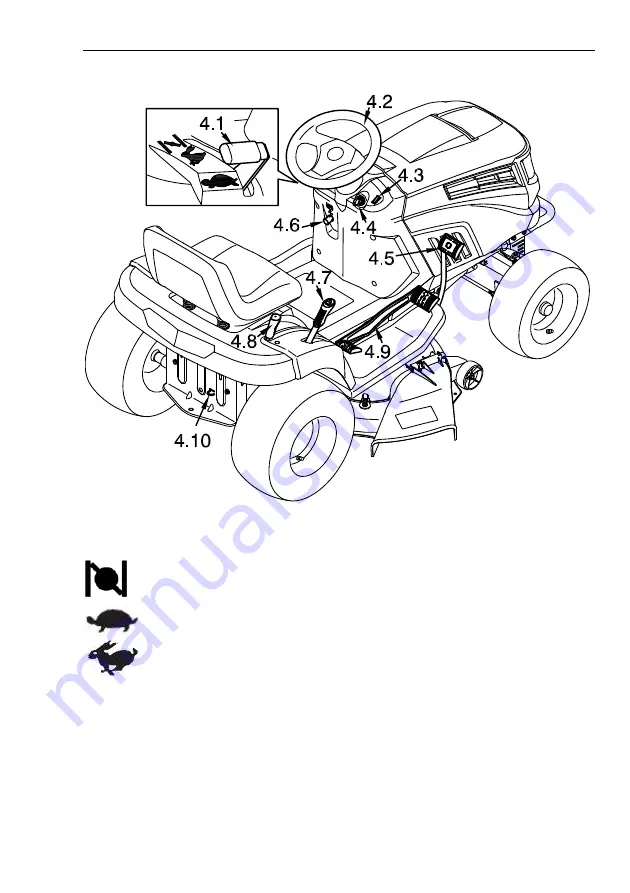

4. CONTROLS AND INSTRUMENTS

4.1 THROTTLE LEVER

This regulates the engine revs, the positions are indicated on a

label showing the following symbols:

«CHOKE» cold starting

«SLOW» for minimum engine speed

«FAST»

for maximum engine speed

– The «CHOKE» position enriches the mixture so must only be used

for the time necessary when starting from cold.

– When moving from one area to another, put the lever in a position

between «SLOW» and «FAST».

– When cutting, shift into «FAST»

4.2 STEERING WHEEL

Turns the front wheels