SLOS289E − DECEMBER 1999 − REVISED SEPTEMBER 2006

16

POST OFFICE BOX 655303

•

DALLAS, TEXAS 75265

APPLICATION INFORMATION

general PowerPAD design considerations (continued)

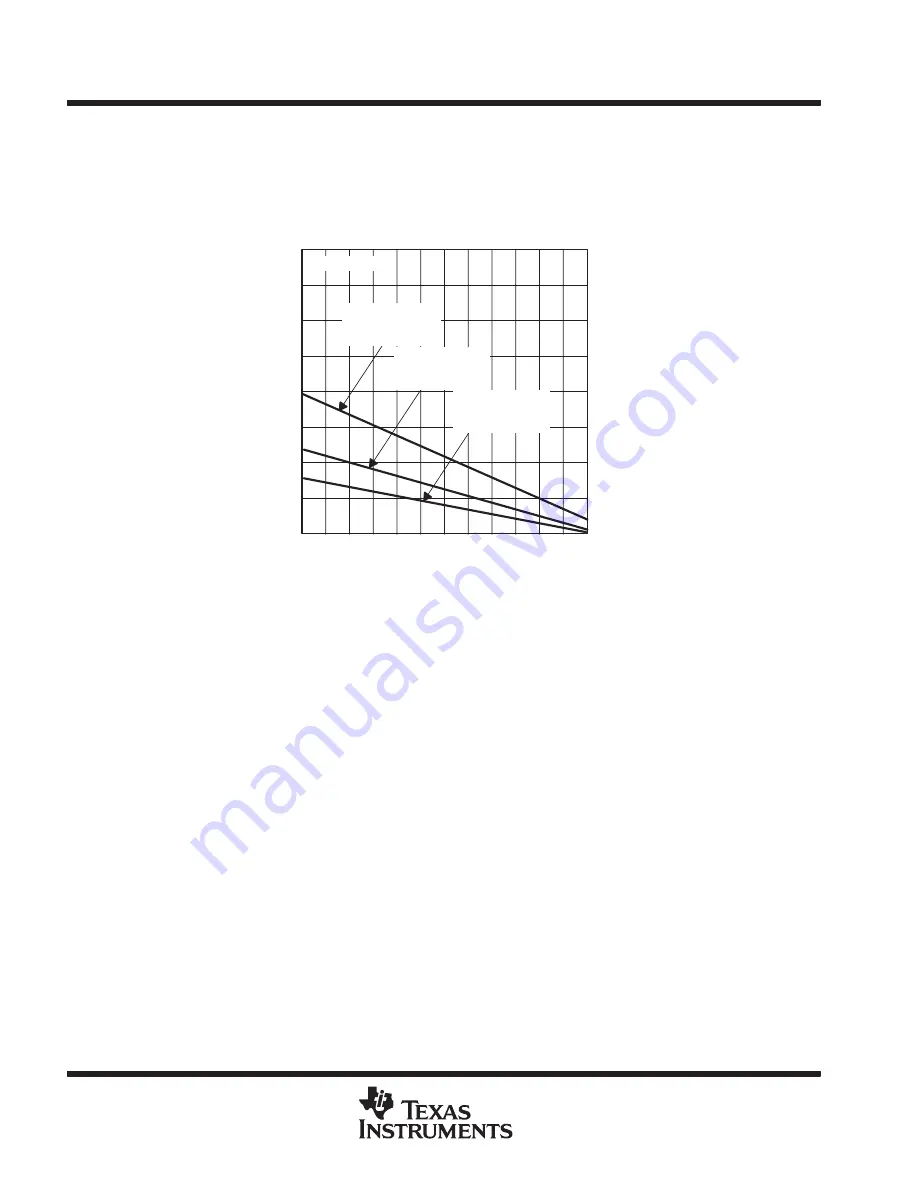

TJ = 150

°

C

4

3

2

0

−55 −40

−10

20 35

Maximum Power Dissipation − W

MAXIMUM POWER DISSIPATION

vs

FREE-AIR TEMPERATURE

65

95

125

1

TA − Free-Air Temperature −

°

C

−25

5

50

80

110

3.5

2.5

1.0

0.5

DGN Package

Low-K Test PCB

θ

JA = 52.7

°

C/W

PDIP Package

Low-K Test PCB

θ

JA = 104

°

C/W

SOIC Package

Low-K Test PCB

θ

JA = 176

°

C/W

NOTE A: Results are with no air flow and using JEDEC Standard Low-K test PCB.

Figure 31. Maximum Power Dissipation vs Free-Air Temperature

The next consideration is the package constraints. The two sources of heat within an amplifier are quiescent

power and output power. The designer should never forget about the quiescent heat generated within the

device, especially multi-amplifier devices. Because these devices have linear output stages (Class A-B), most

of the heat dissipation is at low output voltages with high output currents.

The other key factor when dealing with power dissipation is how the devices are mounted on the PCB. The

PowerPAD devices are extremely useful for heat dissipation. But, the device should always be soldered to a

copper plane to fully use the heat dissipation properties of the PowerPAD. The SOIC package, on the other

hand, is highly dependent on how it is mounted on the PCB. As more trace and copper area is placed around

the device,

θ

JA

decreases and the heat dissipation capability increases. The currents and voltages shown in

these graphs are for the total package. For the dual amplifier packages, the sum of the RMS output currents

and voltages should be used to choose the proper package.