SLUU085 – November 2001

8

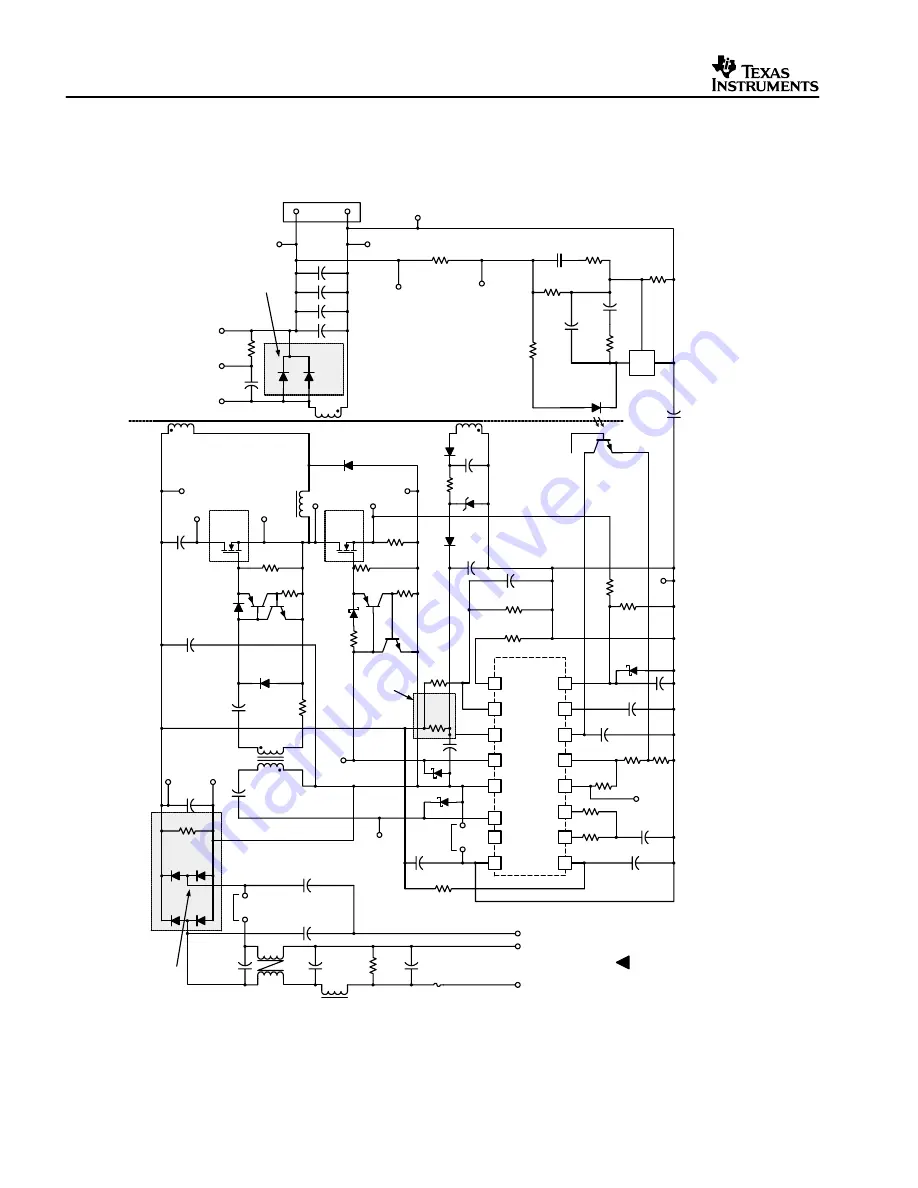

UCC3580EVM

5

Application Drawings and Parts List

5.1

Active Clamp Configuration

UDG–00014

R7

3.92k

R6

5.62k

C14

1

µ

F

50V

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

IC1

UCC3580–

4

DELAY

LINE

VDD

OUT1

PGND

OUT2

CLK

GND

SHDN

SS

REF

EAIN

EAOUT

OSC1

OSC2

RAMP

C9

680pF

C8

470pF

R8

33.2k

R14

33.2k

R13

1.62k

TP12

EAOUT

C17

0.047

µ

F

R17

130k

R10

20.0k

C12

0.01

µ

F

R1

1 51

1k

R16

3.32k

D1

1

1N5819

C18

2200pF

R21 1k

R3

240k

1W

C10

330pF

500V

D7

1N5819

D6

1N5819

C15

0.1

µ

F

R4 47k

2W

W1

Q3

2N3904

R19

15

D9

1N5819

Q1

2N3906

R18

4.7k

R12

10k

QM

IRF740

HS1

R24

0.10

3W

M.E.

TP15

CSENSE

6

5

4

TP14

DRAIN

L3 16

µ

H

2 4

D16

MUR460

TP9

PRI GND

C19

100

µ

F

D14

1N4744

R22 20

C24

0.1

µ

F

D15

MUR120

3

4

3 TURNS

1

2

C21

0.1

µ

F

400V

R23

10k

R15

4.7k

Q2

2N3904

Q4

2N3906

D10 1N4148

TP1

1

OUT2

T1

D5

1N4148

C6

0.1

µ

F

R5 30

C1

1 0.1

µ

F

TP10

OUT1

TP16

SOURCE

TP18

DRAIN

C25

0.068

µ

F

400V

TP17

BULK

24

TURNS

158

µ

H

TP20

BULK

C7

1000

µ

F

TP19

TPI GND

+

R1

68k

1W

D2

1N5406

D1

1N5406

D4

1N5406

D3

1N5406

C2

4700pF

250V

C1

4700pF

250V

J1

–

1

CHASSIS

1

4

5

8

C4 0.1

µ

F

250V

C5 0.1

µ

F

250V

L1

18

µ

H

R2

470k

C3 0.1

µ

F

250V

F1

3A

J1

–

3

LINE

J1

–

2

NEUTRAL

13

14

3 TURNS

2

C34

180

µ

F

C33

180

µ

F

C32

180

µ

F

C31

180

µ

F

++++

R31

NOT

USED

HS3

D17

MBRF2545CT

C30

NOT

USED

TP8

ANODE

TP6

CA

THODE

TP7

SNUB

TP12

+12V

TP1

GND2

TP4

TP5

R32

20

C29

470pF

R29

3.01k

R27

60.4k

C28

4.7nF

R30

54.9k

C26

220pF

IC3

TL431

R28

14.3k

1

3

2

C27

1.0nF 250V

AC

TP3

J2

–

2

RETURN

J2

–

1

+12V

IC2

CNY17

–

2

1

2

AC INPUT

1

15V

60Hz

CAUTION:

LINE VOL

T

AGE

3

1

PRIMAR

Y

SECONDAR

Y

T2

L2

2mH

QA

IRF740

HS2

D13 1N4148

TP13

PRI GND

R26

3.01k

TH1

HIGH

TEMPERA

TURE

–

SEE EVM W

ARNINGS

AND RESTRICTIONS

HIGH

TEMPERA

TURE

–

SEE EVM W

ARNINGS

AND RESTRICTIONS

HIGH

TEMPERA

TURE

–

SEE EVM W

ARNINGS

AND RESTRICTIONS

Note: High-temperature component. See EVM Warnings and Restrictions at the front of this document.

Figure 2. Flyback Converter Populated for Active Clamp Operation