5. Press the water out of the foam element and let it

dry. Put a few drops of SAE-30 oil on the filter to

moisten it lightly. Carefully squeeze any surplus oil

out of the foam element and reattach.

6. Please note that all parts are assembled correctly

and properly closed, as shown in the picture.

Inspection of the blade: Illustration 17

Inspect blade for damage, cracks or excessive rust or

corrosion. Check that the blade bolt is tightened.

Note:

A dull blade can be sharpened! But a blade that

is worn, bent, cracked or otherwise damaged must be

replaced.

Removing and mounting the blade

If you remove the blade to sharpen or replace it, you

must use a torque wrench and some heavy gloves to

protect your hands.

1. Loosen the blade bolts. Use a piece of wood to

prevent the blade from turning around.

2. Remove the bolt, washer, blade and blade holder

in that order

3. Sharpen or replace the blade.

4. Insert the blade holder, blade, washer and bolts in

that order.

5. Tighten the blade bolts again. Use a piece of wood

to prevent the blade from turning around.

Warning

: A blade must be sharpened so it is in

100 % balance, otherwise it may cause vibrations that

could damage the engine. Damage to engine due to

faulty sharpening is not covered by warranty. We

therefore recommend letting a service center sharpen

the blade.

Oil change

Oil should be changed for the first time after 5 hours,

then at least 1 time per year.

You will need an oil extractor kit. Art. no. 40-11336

Oil and oil extractor kit is not included

Use an extractor kit and do as follows:

1. Turn on the engine and let it run for 5 min or until

the engine is hot. A hot engine liquefies the oil

which makes it easier to drain.

2. Suck the oil up through the oil filler hole using the

syringe that came with the oil extractor kit. Use the

hose to reach the sump.

3. Transfer the used oil into a empty container.

4. Fill the engine with SAE-30 oil.

5. Check the oil level using the dipstick. (Min / Max)

Remember to dispose the used oil so that it does no

harm to nature. Use your local recycling station.

The oil level should always be between min. and max

on the dipstick.

Spark plug

1. Remove the spark plug.

2. Brush off dirt from the spark plug.

3. Use a spark plug wrench to loosen the spark plug.

4. Check the insulation is intact.

5. Clean the spark plug with a wire brush.

6. Measure the electrode, taking care not to damage

the electrode.

7. If the spark plug is undamaged refit or replace.

8. Reattach the spark plug.

Storage and maintenance

Maintain your lawnmower:

Check all bolts, screws,

nuts and deck. Dismount the blade and the belt plastic

cover for regular cleaning. Always make sure that the

blade is sharp. It’s a good idea to take your lawn mower

to an annual service check with your authorized service

dealer. See your nearest service center at

www.texas.dk.

Storage:

After use the lawnmower kept in a dry and

clean room. Clean the machine after every use. Grass

and dirt must be removed from the underside of the

deck. By tipping the mower (for cleaning) is

recommended to tilt the front up (max. 45 degrees). If

you tilt it sideways, the carburetor and air filter always

face upwards, since oil may run out and destroy the

engine. Be aware that removing the spark plug before

the mower maintenance.

Winter storage:

Empty the fuel tank and let the engine

run until the gasoline in the carburetor is used up. Spark

plug removed. Remove the spark plug and add a

teaspoon of oil (engine oil) in the hole. Pull the starter to

distribute oil. Mount the spark plug, but not the spark

plug cap. Change oil as described in the section above.

Spray silicone lubrication into the cables and move

them.

Finally, clean the mower thoroughly. Dip a cloth in oil

and luricate metal parts to prevent rust.

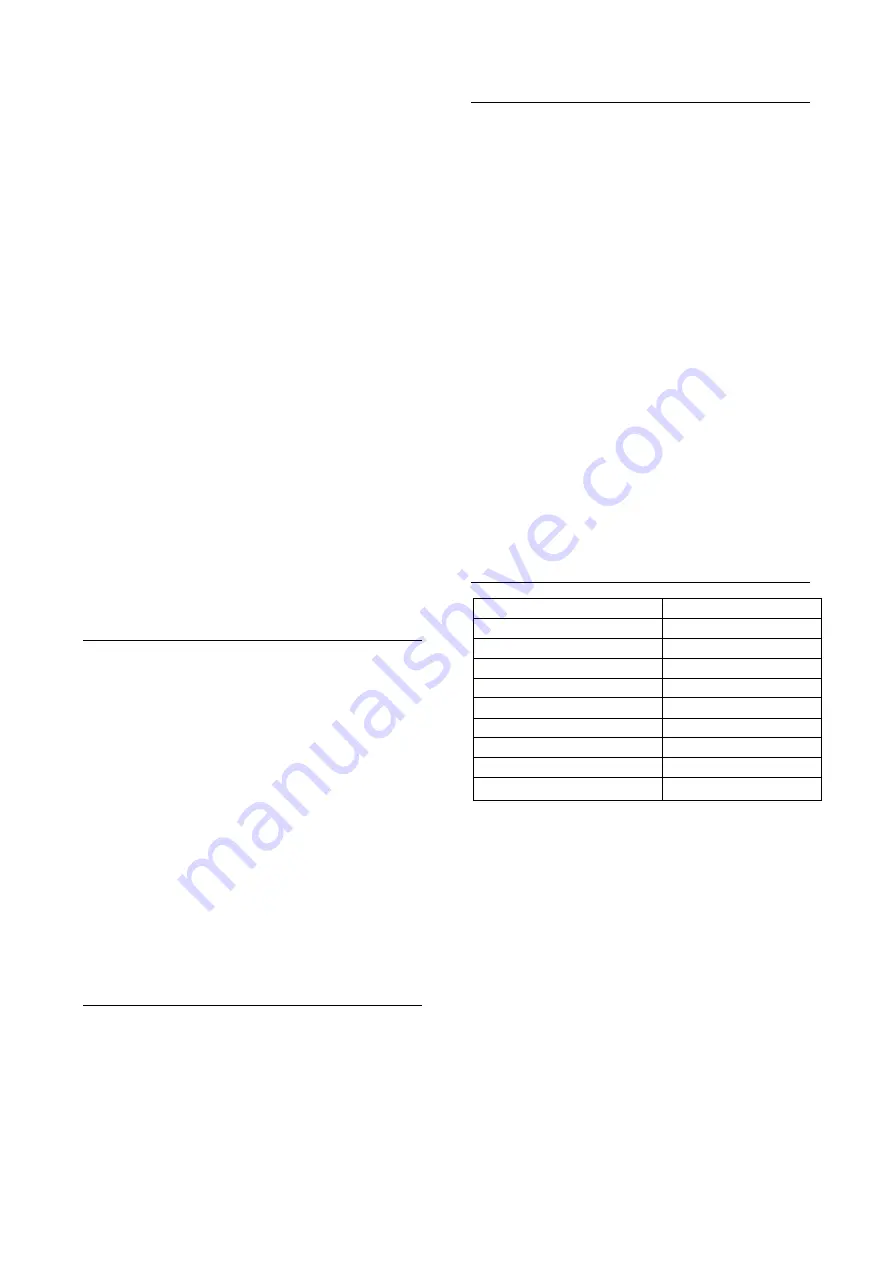

Technical data

Model

Multi Cut 610

Engine model

Loncin - LC1P70FA

Self-drive speed

1.4 - 3.6 km/h

Engine displacement

196 cc

Nominal power

3.6 kW

Cutting width

61 cm

Max.Engine speed

3600/min

Fuel tank capacity

1 L

Height adjustment

25-75 mm, 4 positions

Net weight

60 kg

Summary of Contents for Multi Cut 610

Page 2: ...Illustrationer Illustrations Abbildungen Illustrationer Illustrations Abbildungen 1...

Page 3: ...2 3 4 5 A B...

Page 4: ...6 7 8...

Page 5: ...9 10 11 12 13...

Page 6: ...14 15...

Page 7: ...16 17...