Operation Manual – TEXI 781 SERVO

Adjusted confirmation method:

The stop frame is adjusted to a high speed running state, and the manual stop handle is rotated,

the stop block must release a first gear, enter a low speed state, and then release the second gear

to enter a stop state.

The phenomenon when the adjustment value changes:

(1)

At the parking position, the clearance between the stop sub-block A and the stop lever block

B is too small, and there is no stopping.

(2)

When the hex nut loosens and the sewing machine stops, the height of the needle changes.

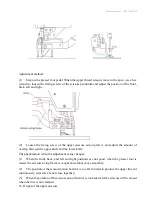

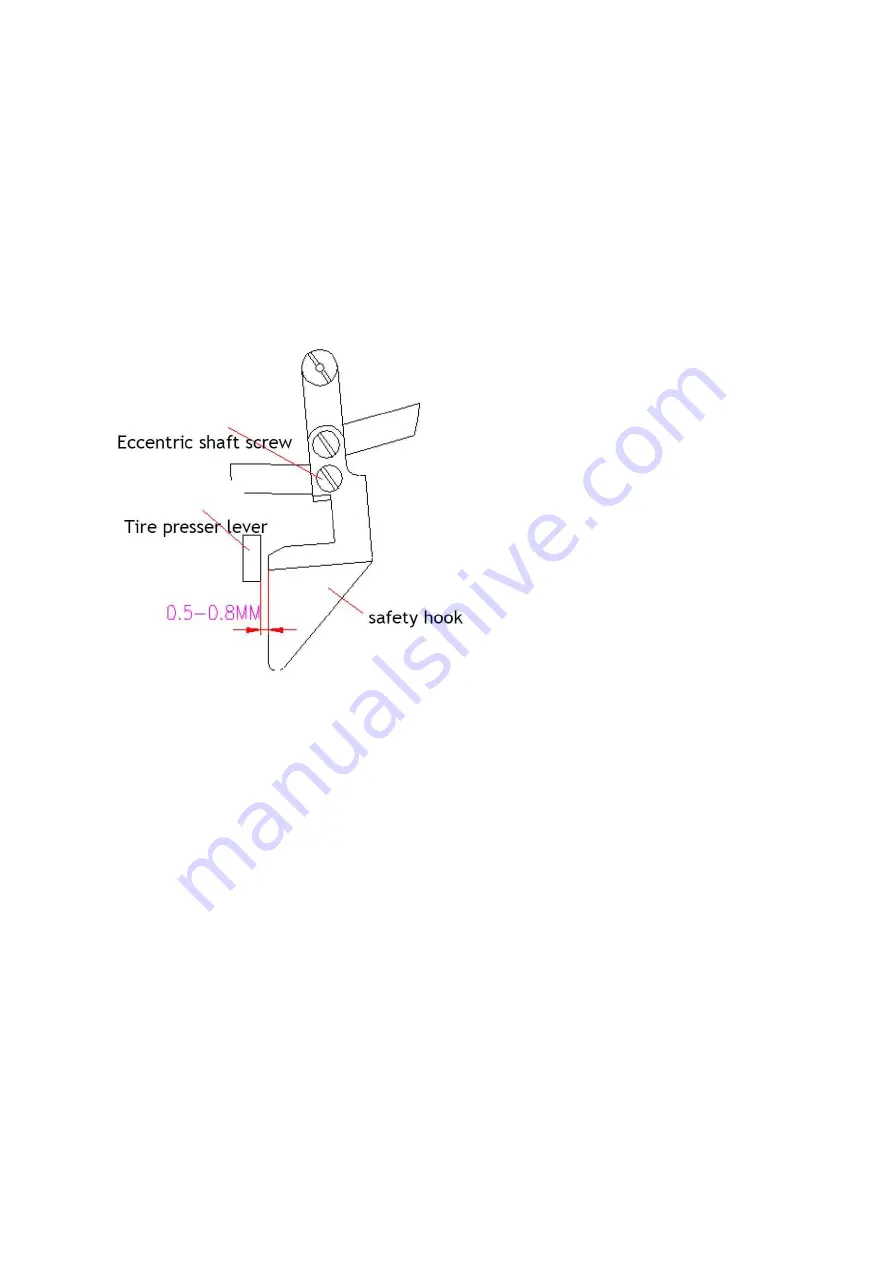

13.

Start

the

position

of

the security hook

Adjustment requirements:

When parking, the distance between the start safety hook and the lifter lever is 0.5~0.8mm.

Adjustment method:

Adjust with the rotating eccentric shaft screw.

The phenomenon when the adjustment value changes:

If there is no gap, it will be in a state of conflict, causing the presser foot not to return. On the

contrary, if the gap is too large, it will not stop.

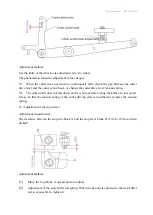

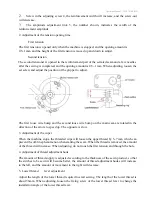

14.

The amount of back and forth movement of the upper knife

Adjustment requirements:

The amount of back and forth movement is 4~5mm.

Adjustment method:

(1)

Loosen the roller shaft fixing screw in front of the presser foot connecting rod, adjust the

amount of back and forth movement of the upper knife, move to the right to increase the

amount of movement, and shift to the left to decrease.