Operation Manual – TEXI 781 SERVO

(3)

At this time, adjust the gap between the hook positioning hook and the hook to 0.5mm, and

loosen the screw of the hook positioning hook to adjust. (Keep the line pass smoothly)

The phenomenon when the adjustment value changes:

(1) When sewing elastic fabric, slow down the cooperation time of the hook to the needle, and

the effect is better. (The distance between the tip of the hook and the upper end of the needle eye

is about 1.0mm)

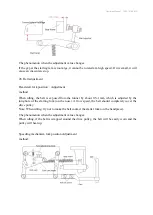

3. Matching of the baseline adjustment handle (adjusting the parallel gap between the cutter and

the left and right amplitudes)

Adjustment requirements:

(1)

Position of the parallel portion on the left side: The lower end of the left baseline adjustment

screw is 10 mm from the upper plane of the baseline adjustment handle, and the lower plane of

the baseline adjustment handle is exposed to be about 1 mm.

(2)

Position of the right parallel portion: The adjustment of the right baseline should be

adjusted to the A=B position according to the amplitude of the parallel portion.

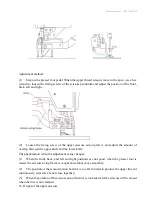

Adjustment method:

(1)

Adjustment of the left baseline should be performed when the needle falls in the center of the

needle plate hole. The distance between the lower end of the left baseline adjustment screw

and the plane above the baseline adjustment handle is approximately 10 mm, which is adjusted

by the left baseline adjustment screw (see figure).

(2)

The adjustment of the right baseline is performed with the right baseline adjustment screw.

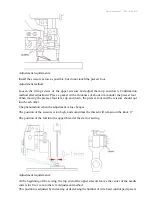

(3)

Adjust the left and right baselines so that the cutter falls in the center of the parallel portion.