Operation Manual – TEXI 781 SERVO

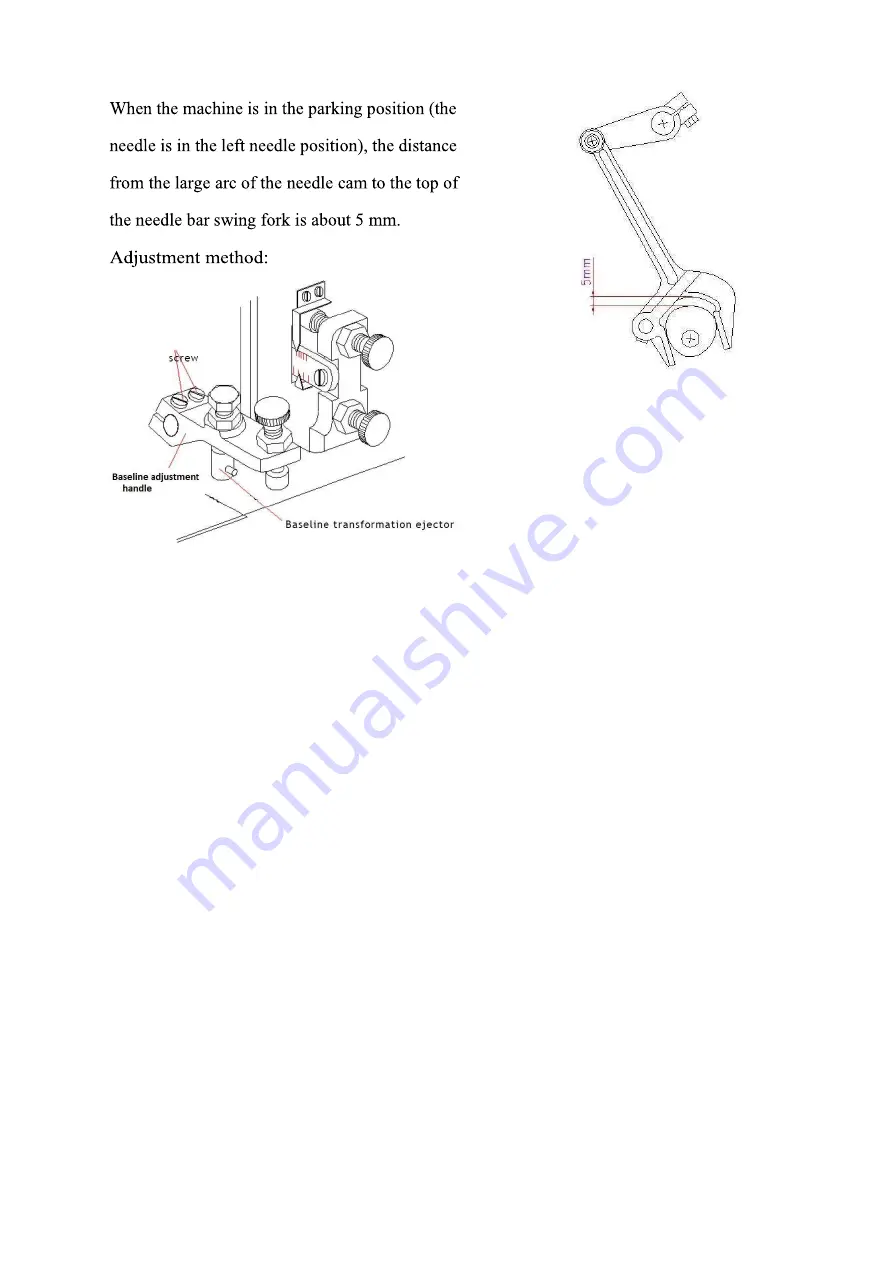

When the machine is in the parking position (the needle is in the left needle position), loosen the

fastening screw on the baseline adjustment handle, push down the needle bar swing fork, so that

the large arc of the needle swing cam is convex to the top of the needle bar swing fork About

5mm, adjust the shank to the baseline adjustment shank, and then tighten the baseline adjustment

shank.

Note: When making this adjustment, please remove the spring of this mechanism and adjust it.

Check if the needle-swing cam of the needle-spindle gear rotates smoothly.

The phenomenon when the adjustment value changes:

If the height of the needle bar swing fork is not accurate, the width of the left and right courses

will be different.

7.

The position of the under feeding crank

Adjustment requirements:

Even if the sewing size (adjustment button hole length) is changed, the position of the

presser foot does not change during parking, and the position of the feed carriage does not change.