Operation Manual – TEXI 781 SERVO

Adjustment method:

Rotate the main cam with the manual feed handle. When the main cam engraving line is aligned

with the center of the roller pin screw of the feeding lower crank, loosen the fastening screw of

the lower crank and then loosen the button hole length nut. When the plate moves to a distance

of 2.5mm from the needle plate (see picture), move the button hole length adjustment screw in

the arc groove of the feed crank body. If the presser foot does not move back and forth, the

position of the crank under the feed is correct. When the crank body does not move, tighten the

fastening screw of the lower crank.

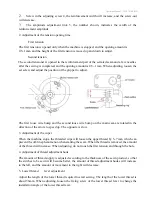

The phenomenon when the adjustment value changes:

If the position is wrong, whenever the sewing size is changed, the action of the scissors will

fail, and the position of the presser foot will also change, causing a broken needle or thread

broken.

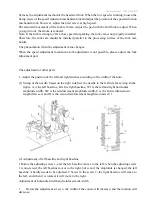

8. Front and rear position of the presser foot

Adjustment requirements:

The gap between the center of the needle drop hole and the inner end surface of the presser foot is

2.5 mm (when the vehicle is parked), and the presser foot plate is located at the same position on

both sides of the needle blade slot.

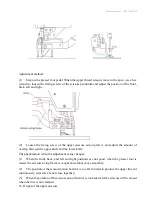

Adjustment method:

When the machine is in the parking position, loosen the fastening screws of the pallet to adjust.

Confirmation after adjustment: Please confirm

that

the

lifting arm

is

perpendicular to the bottom plate.

The phenomenon when the adjustment value changes: