Operation Manual – TEXI 781 SERVO

(1)

If the position of the presser foot is not accurate, the front and rear positions of the presser

foot are not accurate, and the opening and closing action of the upper scissors action plate is

affected.

(2)

When the parking is stopped, the gap between the center of the needle hole and the presser

foot is too small. When the sewing machine is in contact with the presser foot during sewing, the

thread is broken and the needle is broken.

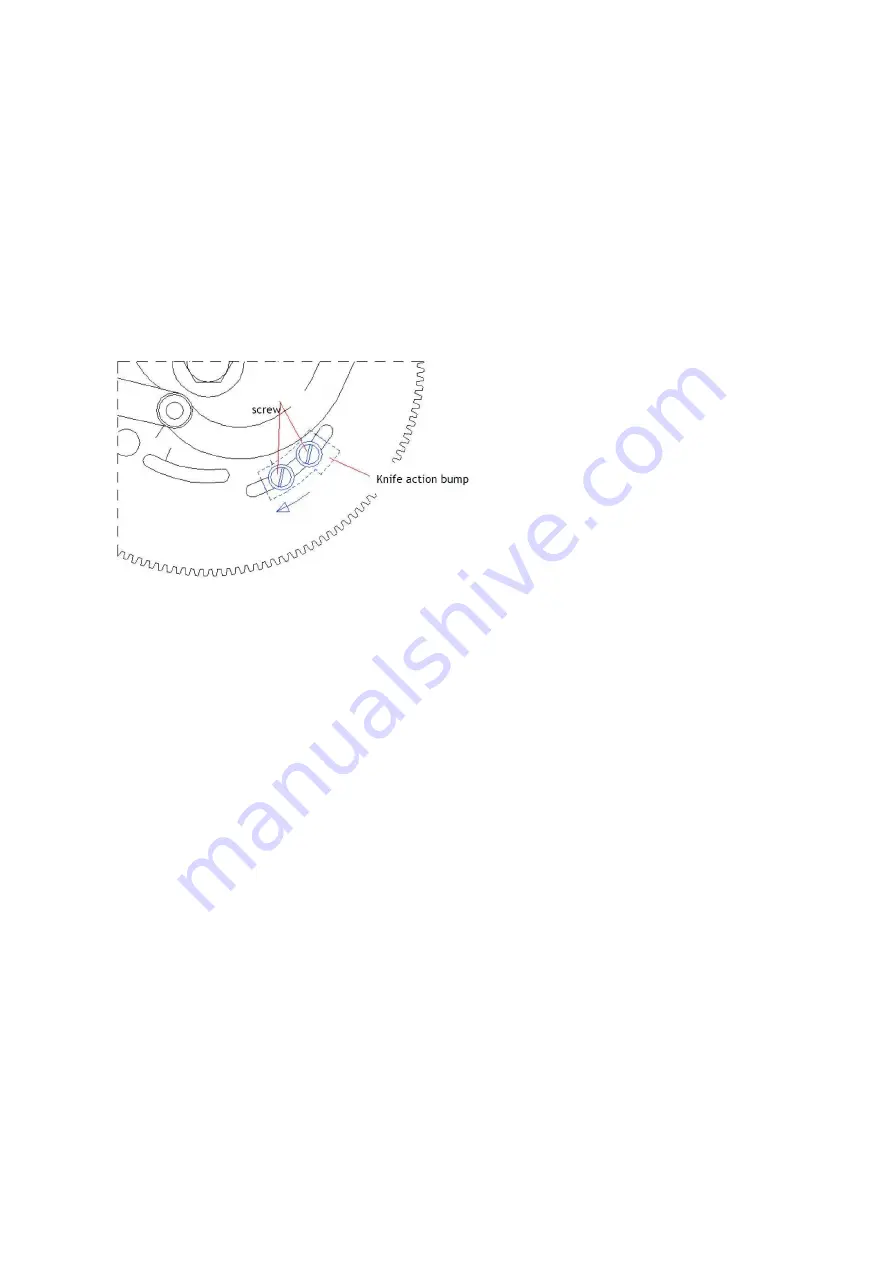

9. Cutter falling time

Adjustment requirements:

After the sewing machine is completely decelerated, it will fall 2~3 before the stop (1 2 3 pin is

the reference).

Adjustment method:

Move the cutter action bump position and adjust the cutter fall time to 2~3 stitches before the

sewing machine stops.

Moving in the direction of the mark, the cutter falls early.

Note: When the number of stitches is adjusted to 93 or less, adjust the low speed bumps.

The phenomenon when the adjustment value changes:

When the cutter is operated during high-speed operation, the cutter will not fall, and the cutter

will be accelerated.

10.

The position of the cutter falls

Adjustment requirements:

Should fall in the middle of the needle plate slot.

Adjustment method:

Loosen the needle plate seat fastening screw and move the needle plate seat position to adjust.

The phenomenon when the adjustment value changes:

When the position is wrong, the cutter hits the needle plate.

11.

Knife of action hook position

Adjustment requirements:

The clearance between the cutter drive lever and the knife of action hook at the lowest point is

0.05~0.2mm.