Summary of Contents for XYZ 2517

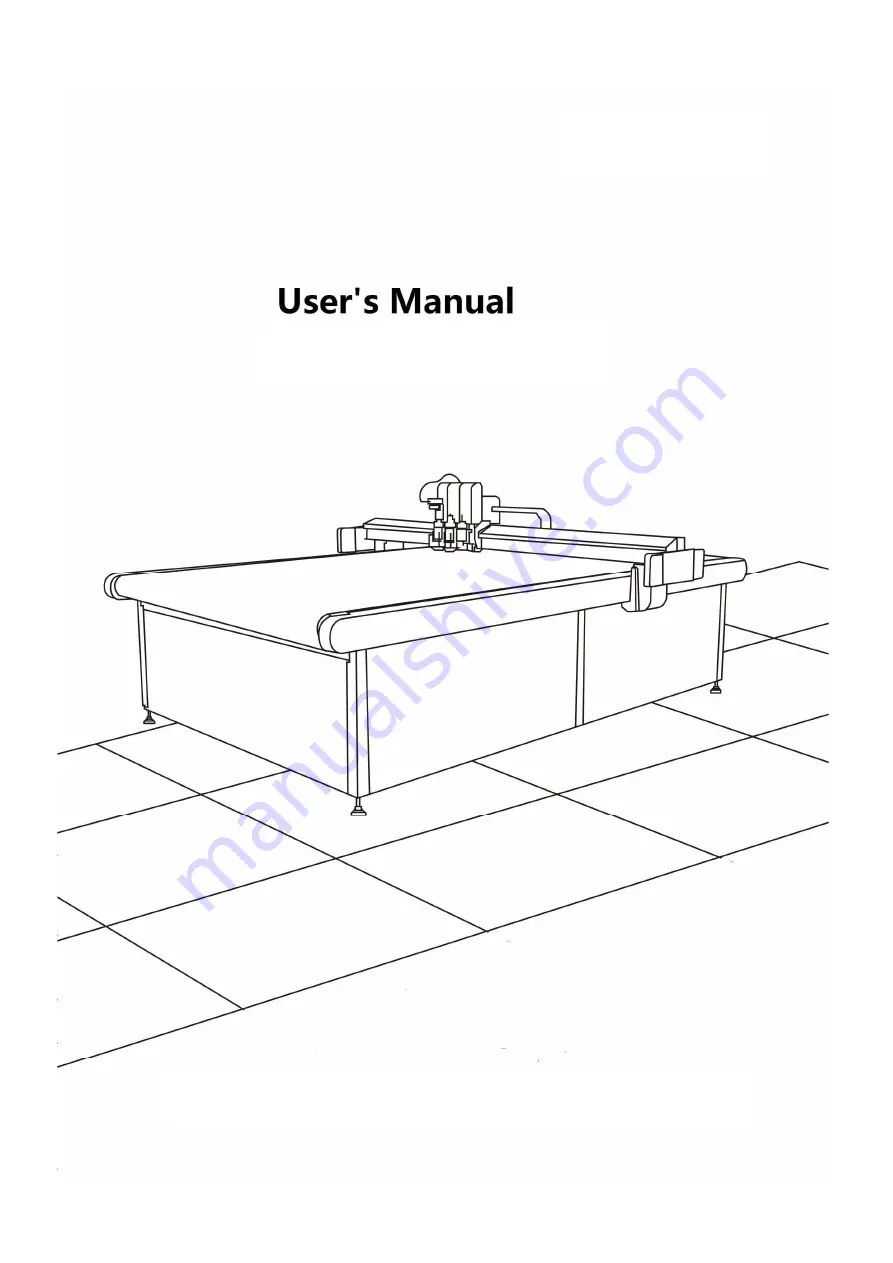

Page 1: ...TEXI XYZ 2517...

Page 4: ......

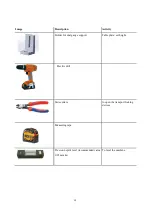

Page 17: ...13 Without Length Length 2 4m Width Width 2 4m...

Page 19: ...15 M16 x 70mm...

Page 20: ...16 3 3 Base machine installation Picture 1...

Page 21: ...17 Picture 2...

Page 22: ...18 Picture 3 Picture 4...

Page 26: ...22 3 5 Assemble the Milling support device The total height 2 8 m...

Page 27: ...23 3 5 1 Connect cables in the milling device support...

Page 31: ...27...