example, if the number is 500, press

and hold for 2-5 seconds or

until the cutter head stops moving, the distance of the cutter head

moving is 500mm

(Note:If just tap the direction button, the corresponding axis movement

distance is not the set value distance)

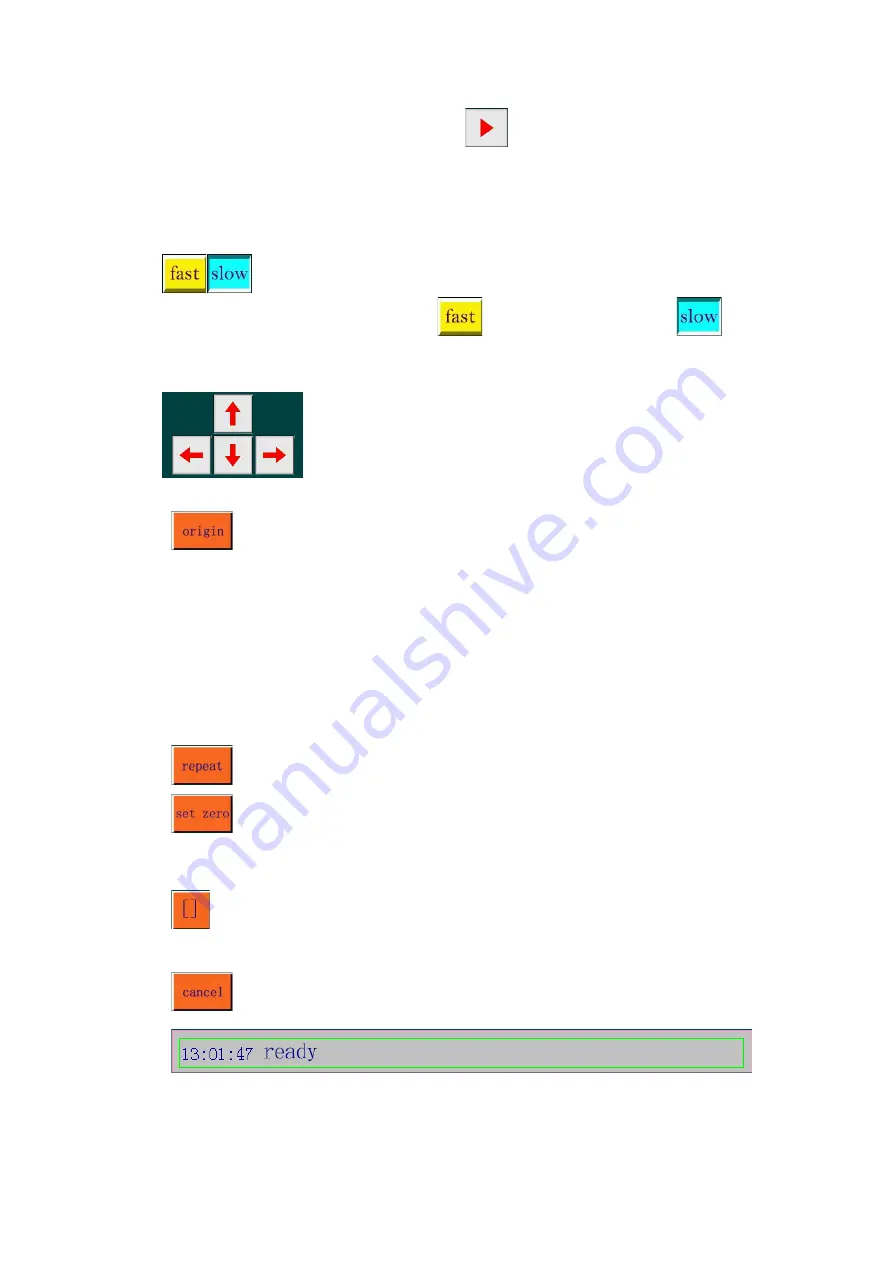

(8)

,

They are used to switch the moving speed of the cutter

head during manual operation.Press

and it will become to

,

the

moving speed of the cutter head will be slow during manual operation

,

it is suitable for fine-tuning the cutter head position.

(9)

These buttons can move the cutter heads and beam

to the corresponding border of the working area.

(10)

When the machine is powered on, the coordinates will be

initialized to 0, but the actual coordinates of the cutter head may

not be 0 at this time, so it is necessary to go to the origin point,

so as to make the coordinates of the control system consistent with

the actual positions of each axis. When going to the origin point, the

cutter head will move in a certain direction. When the corresponding

limit sensor is triggered, the machine will make correction action,

and then stop the movement. The control panel shows that

“

go origin

succeed

”

.

(11)

It is equivalent to the start function.

(12)

Set the position illuminated by the laser lamp to the new

zero point,it is equivalent to the start point of cutting.But it is

not the real starting point of cutting.

(13)

Frame, check the rectangular range occupied by the current

processing file

(14)

Cancel all current actions of the machine.

(15)

①

Status bar

,

display the current status of the machine.

②

Pause

,

During processing the graph, press the status bar,the machine

Summary of Contents for XYZ 2518

Page 1: ...TEXI XYZ 2518 MANUAL...