37

2-2. Basic Configuration

The basic configuration settings are the common configuration

settings that are used for each operating mode. After selecting a

basic operating mode (CC, CR, CV or CP mode), the slew rate,

switching mode, response rate and other common parameters should

be configured.

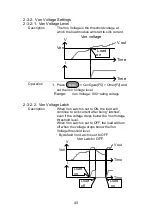

2-2-1. Select the Switching Function

Description

The LSG Series has two switching modes, static

and dynamic. The switching modes allow the

LSG Series to switch between two preset levels.

Static mode can only switch between the two

levels manually, while Dynamic mode switches

between each level automatically based on a

timer.

Static mode: A Value, B Value

Dynamic mode: Level1, Level2

When the unit is set to static mode, only one

value (A Value or B Value) can be active at a

time. The active value is shown in the Operation

Status Panel.

Function

Static

Configure

0.00

w

LOAD

RS232

SHORT

A Value

Fine

W

W

Active setting

When the unit is set to dynamic mode, the unit

will switch between Level1 and Level2 based on

the Timer1 and Timer2 parameters, shown

below.

Level

Time

Level 2

Level 1

Timer1 Timer2 Timer1

Dynamic Mode

Note

Dynamic mode is not available for CV mode.

Summary of Contents for LSG SERIES

Page 8: ......

Page 23: ...11 GRA 414 E EIA standard 132 382 5 477 6 GRA 414 J JIS standard 149 382 5 477 6 ...

Page 149: ...137 7 6 Operating Area LSG 175 ...

Page 150: ...138 LSG 350 ...

Page 151: ...139 LSG 1050 ...

Page 166: ......