Texmate, Inc. Tel. (760) 598-9899

Page 2

3/31/00 DI-45U Data Sheet (DI2)

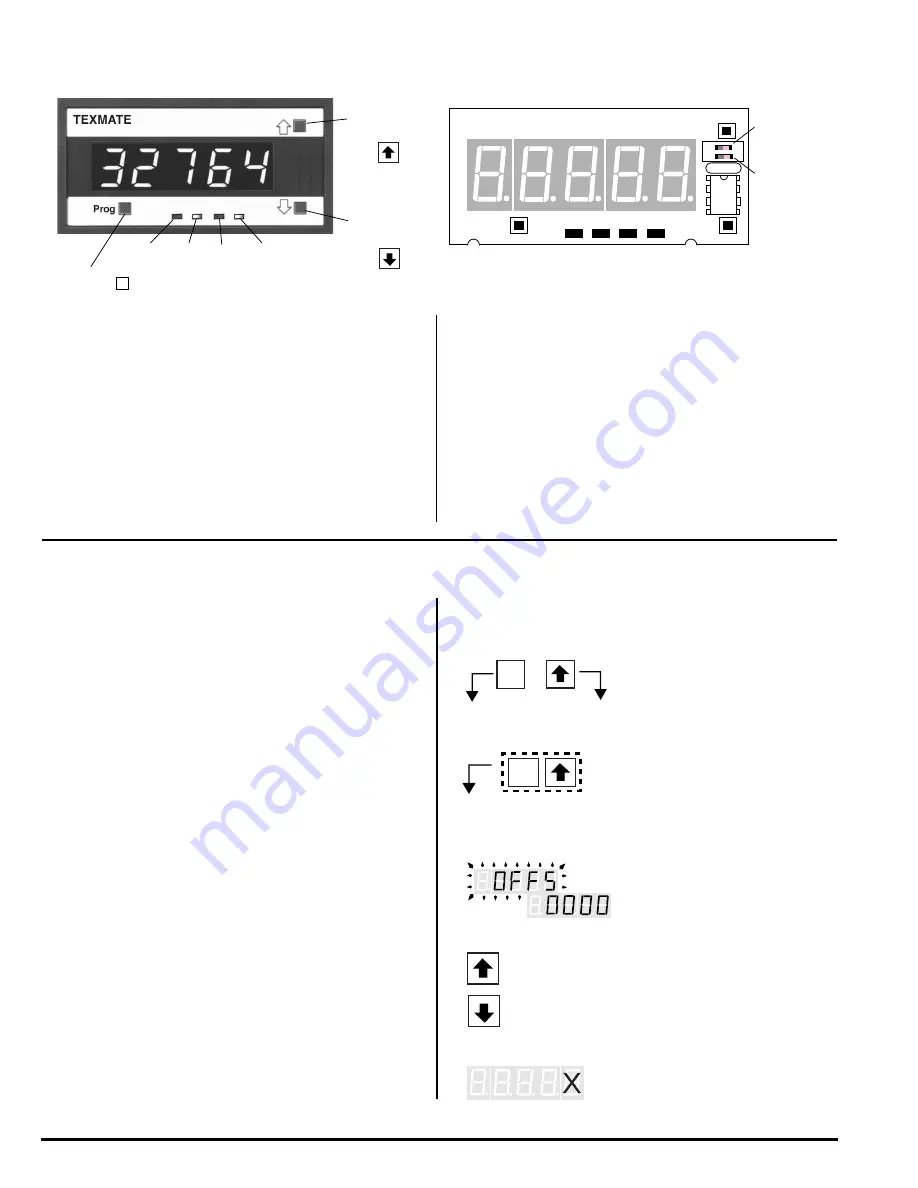

FRONT PANEL FUNCTIONS

UP ARROW

BUTTON

DISPLAY WITH FACEPLATE AND BEZEL

OFF

1

2

DOWN

ARROW

BUTTON

DISPLAY BOARD WITHOUT FACEPLATE

L1

H1

ANNUNCIATORS

L2

H2

BASIC METER OPERATION

STANDARD PROGRAMMING

The resident software in the DI-45U TIGER CUB has been

designed for maximum user flexibility while maintaining an intel-

ligible programming process. This 'intuitive' software, unique to

the Texmate DI-45U TIGER CUB, allows quick understanding of

the meter's capabilities while allowing the user to be in control.

The software set up can be accomplished via the three front

panel buttons (Prog./Up arrow/Down arrow.) To begin, these

three buttons allow the user access to input scaling (MX+B),

baud rate selection, setting of an address and display bright-

ness. These first selections are then followed by the program-

ming of a series of four 3-digit codes. Each digit within a single

code represents a specific function of the DI-45U TIGER CUB.

The user can customize the meter to their exact needs. If a

function requires change after the initial set up, all previous

selections can be ignored (skipped) and only the specific code

affecting the function in question needs to be changed. This

unique code structure makes software modifications fast and

easy. Texmate has Technical Staff on call to assist you in this

process should the need arise.

MeterBOSS

TM

SOFTWARE

As an option, Texmate offers MeterBOSS software which can

be accessed through the serial port from your personal comput-

er. This is in addition to our standard DI-45U TIGER CUB meter

package and allows the user to display and modify data direct-

ly on the PC screen. MeterBOSS software is explained fully on

page 9 of this bulletin.

EXAMPLE PROGRAMMING SYMBOLS

Symbol

Explanation

PROGRAM BUTTON: This button is used to move from one

program step to the next.

When used simultaneously with the UP ARROW button, it initi-

ates the Programming Mode.

When used simultaneously with the DOWN ARROW button, it

initiates the Setpoint Program.

UP ARROW BUTTON: Increases the value of the displayed

parameter.

DOWN ARROW BUTTON: Decreases the value of the dis-

played parameter.

ANNUNCIATORS: May be programmed to indicate the setpoint

status. They are labeled L2, L1, H1, H2.

PROGRAM LOCKOUT SWITCH: Once the program has been

entered, this switch will not allow any changes to be made

except for the setpoints. If programming is attempted, the DI-

45U TIGER CUB will display 'LOC'. Parameters may still be

viewed but not changed.

SETPOINT LOCKOUT: Once the setpoint values have been

entered this switch will not allow changes to be made except for

the program. If setpoint programming is attempted, the DI-45U

will display 'LOC'. Parameters may still be viewed but not

changed.

PROGRAM

BUTTON

P

When a button is shown, press and

release it to go onto the next step in

the direction indicated by the arrow.

P

When two buttons are shown side by

side and enclosed by a dotted line, they

must be pressed simultaneously then

released to go onto the next program-

ming step. For example, the symbols

shown at left indicate the user is to

press the Program button and the Up

Arrow button simultaneously together.

The display toggles (flashes) be-

tween the name for the function

and the value.

When these buttons are shown together, the dis-

play value can be increased by pressing the Up

Arrow button or decreased by pressing the Down

Arrow button. Note: When pressed for a few sec-

onds, the rate of change increases.

P

If an X appears through a digit, it

means to that any number displayed

in that digit is not relevant to the

function being explained.

PROGRAM

LOCKOUT

SETPOINT

LOCKOUT