Page 41

6/23/04 DI-50B51 320 Series (NZ306)

Texmate, Inc. Tel. (760) 598-9899

•

www.texmate.com

Up to 4000 samples can be logged within the meter in the cyclic

or linear FIFO mode and saved for later downloading to a PC,

using a terminal evaluation program, or printing directly to a

serial printer.

Data logging can be triggered (activated) from a setpoint, the

program button, or from an external switch. See the 3rd digit in

the diagram below.

Data from up to four selectable registers can be logged with one

of the following printer or spreadsheet style time and date

stamps. All time and date stamps are generated from an option-

al real-time clock (see the 2nd digit in the diagram below):

•

No time stamp.

•

Month - Day - Year. Hours:Minutes:Seconds.

•

Day - Month - Year. Hours:Minutes:Seconds.

•

Hours:Minutes:Seconds.

Printer style time and date stamps have a carriage return and

line feed. Spreadsheet style time and date stamps are continu-

ous on a single line.

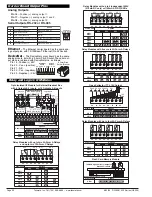

CODE 8

–

DATA LOGGING AND PRINT MODE OPTIONS

FIRST DIGIT

SECOND DIGIT

THIRD DIGIT

FIRST DIGIT

SECOND DIGIT

THIRD DIGIT

DATE & TIME STAMP OPTIONS

0 Printer Format

–

No time stamp with

print/log

1 Printer Format

–

Time stamp format 1 [Mth-

Day-Yr Hrs:Min:Sec] (with <CR><LF>)

2 Printer Format

–

Time stamp format 2 [Day-

Mth-Yr Hrs:Min:Sec] (with <CR><LF>)

3 Printer Format

–

Time stamp format 3

[Hrs:Min:Sec] (with <CR><LF>)

4 Spreadsheet Format

–

No time stamp with

print/log

5 Spreadsheet Format

–

Time stamp format 1

[Mth-Day-Yr Hrs:Min:Sec]

6 Spreadsheet Format

–

Time stamp format 2

[Day-Mth-Yr Hrs:Min:Sec]

7 Spreadsheet Format

–

Time stamp format 3

[Hrs:Min:Sec]

ALL ABOVE ARE REAL-TIME CLOCK OPTIONS

LOG OR PRINT TRIGGER

0 No trigger

1 Trigger on Demand from PRO-

GRAM Button

2 Trigger on Demand from F1 Button

3 Trigger on Demand from F2 Button

4 Trigger on Demand from HOLD Pin

5 Trigger on Demand from LOCK Pin

6 -

7 -

Note:

Log and/or print will only

trigger if enabled.

The TEST, HOLD, and LOCK pins are located at the rear of the

meter to accommodate external switched digital inputs. When

switched to the COMMON pin, they can be programmed in

Code 9 to perform remote resetting functions to add to the func-

tionality of the meter.

DISPLAY TEST PIN

0 Display test only

1 Reset Counter Channel 1 and Sub-

total at Power-up

2 Reset Counters Channel 1, 2, 3, 4,

Total 1, and Total 2 at Power-up

3 Reset Total 1, and Total 2 at Power -up

HOLD PIN

0 Display Hold

1 Reset Channel 1

2 Reset Total 1 and Total 2

3 Reset Total 2

4 Reset Peak, Valley

5 Reset Tare

6 Set Tare

7 Unlatch (de-energize) all Setpoints

LOCK PIN

0 Key Lock

1 Reset Channel 1

2 Reset Channel 2

3 Reset Channel 3

4 Reset Channel 4

5 Reset Tare

6 Reset Total

7 Unlatch (de-energize) all Setpoints

CODE 9

–

FUNCTIONS FOR DIGITAL INPUT PINS

DATA LOG BUFFER TYPE

0 No Data Logging

1 Cyclic Buffer

2 Linear FIFO Buffer.

3 Reset Buffer Number to 0.

Note:

Setting Code 8 to [3XX] resets the

data log buffer to 0. Once reset,

Code 8 must be set back to the

required data log buffer setting.

Note:

CAPTURE, HOLD, and LOCK pins can be a setpoint acti-

vation source. See Setpoint Programming mode.

I

n

i

ti

al

S

e

t

up P

r

o

c

e

du

r

e

s

[

C

o

d

E

_

8

]

-

D

ata

L

oggi

n

g

&

P

r

i

n

t

M

o

d

e

I

n

i

ti

al

S

e

t

up P

r

o

c

e

du

r

e

s

[

C

o

d

E

_

9

]

-

F

un

c

ti

o

n

s

f

o

r

D

i

gital

I

npu

t

P

i

n

s

See

Serial Communications Module Supplement (NZ202)

for full details on the Data Logging and Print Mode

Options.