Page 2

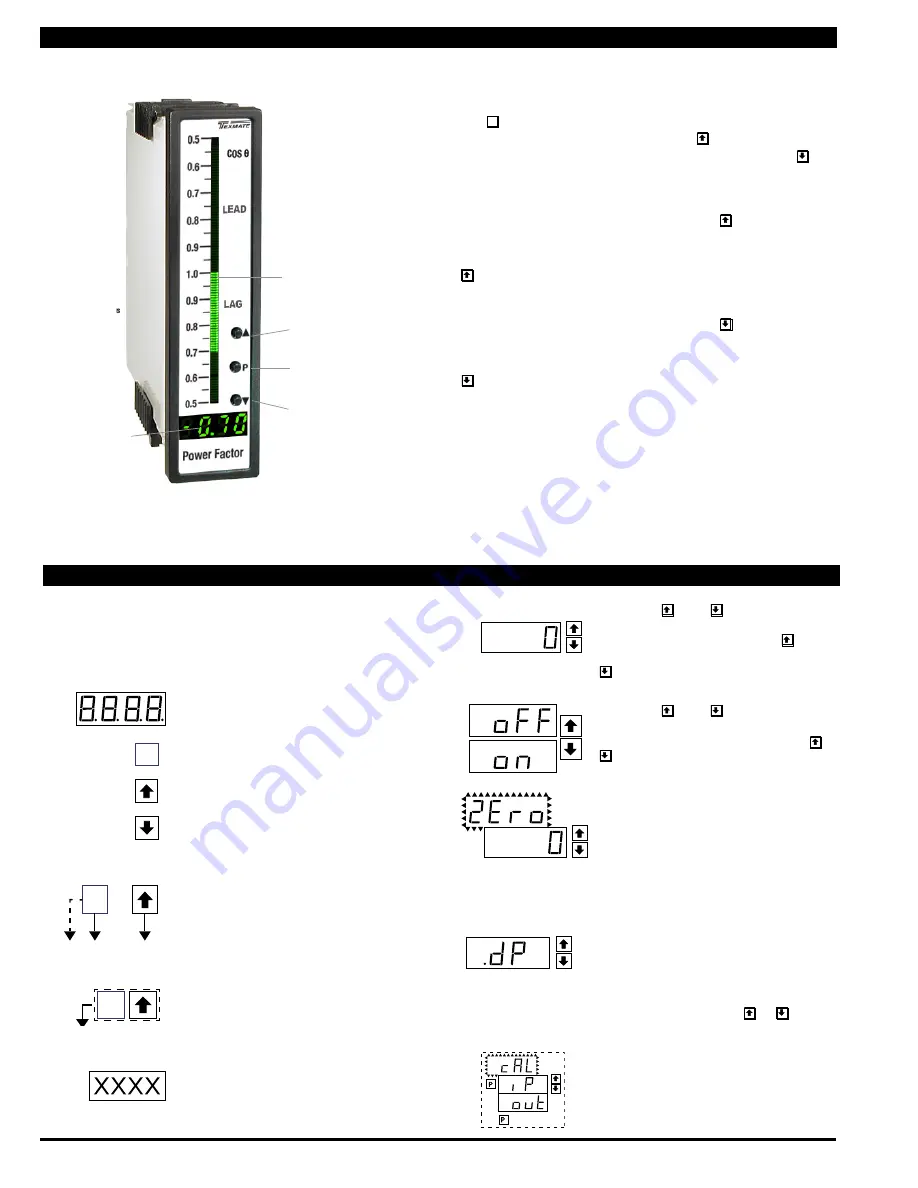

FL-B101D40PF Power factor (D0109) Manual

UP

Button

DOWN

Button

PROGRAM

Button

Seven Segment

LED Display

101 Segment

Bargraph

Front Panel Buttons

Program Button

The

P

button is used to move from one program step to the next.

When pressed at the same time as the button, it initiates the

calibration mode. When pressed at the same time as the but-

ton, it initiates the setpoint setting mode.

Up Button

When in the operational display, pressing the button allows you

to view the setting of the saved Peak and Valley Values.

When setting a displayed parameter during programming, the

button is used to increase the value of the displayed parameter.

Down Button

When in the operational display, pressing the button allows you

to change the Brightness Level.

When setting a displayed parameter during programming, the

button is used to decrease the value of the displayed parameter.

Front Panel LED Display

Digital LED Displays

The digital LED displays are used to display the meter input

signal readings. They also display the programming settings

during programming.

Controls and Indicators

This symbol represents the

OPERATIONAL DISPLAY.

This is the PROGRAM button.

This is the UP button.

This is the DOWN button.

When a button is shown, press and

release it to go onto the next step in the

direction indicated by the arrow. When

an alternative dotted line is shown, this

indicates that an alternative logic branch

will be followed when a particular option

is present.

When two buttons are shown side by side

and enclosed by a dotted line, they must

be pressed at the same time then released

to go onto the next programming step.

If an X appears through a digit, it means that

any number displayed in that digit is not rel-

evant to the function being explained.

P

[Span]

[10000]

P

P

When the

and

buttons are shown

together, the display value can be increased

by pressing and releasing the

button

or decreased by pressing and releasing the

button.

When the

and

buttons are shown

with two displays, either display can be

selected by pressing and releasing the

or

buttons.

When two displays are shown together

with bursts, this indicates that the display is

toggling (flashing) between the name of the

function and the value.

Text or numbers shown between square

brackets in a procedure indicate the pro-

gramming code name of the function or the

value displayed on the meter display.

When there are more than two display selec-

tions they are shown in brackets below the

first display and are also selectable by

pressing and releasing the

or

buttons.

A dotted line enclosing an entire logic dia-

gram indicates that programming branch

will appear only when a particular option is

present.

To explain software programming procedures, logic diagrams are

used to visually assist in following the programming steps. The

following symbols are used throughout the logic diagrams to

represent the buttons and indicators on the meter:

Programming Conventions

[X•XXX]

[XX•XX]

[XXX•X]

[XXXX•]

[XXXX]